Description

Main Specifications of M10*200MM Two Die Three Blow Special Parts Forming Machine

| Model | Unit | AH23-10LL |

| Stations | Pcs | Two die three blows |

| Appro.Dimension | Cm | 400*200*180 |

| Machine Color | Customized | |

| Suitable Product Size | M6-M10 | |

| Max. Product Length | Mm | 200 |

| Min. Product Length | Mm | 30 |

| Max. Production Speed | Pcs/Min. | 40 |

| Main Motor Power | Kw | 11 |

| Appro. Machine Weight | Ton | 7 |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

Application Scope of M10*200MM Two Die Three Blow Special Parts Forming Machine

Two Die Three Blow Special Parts Heading Machine is one kind of specialized machine with high efficiency and automation among forging machinery. Two Die Three Blow Special Parts Heading Machine are used for producing different kinds of self tapping screws,rivets,hinge pin and special parts in the field of fastener industry. Because of the advantage of the cold forging equipment itself and the superiority of cold forging technique, the Two Die Three Blow Special Parts Heading Machine also are widely used in different national economic fields for producing fasteners and non-standard parts for industry of building,aviation steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc.

Items can be produced by the M10*200MM Two Die Three Blow Special Parts Forming Machine

self tapping screws,rivets,hinge pin and special parts,chipboard screw,particle board screw,double ended screw,dowel screw,hanger bolt,drywall screw,lag screw,mirror screw,sheet metal screw,Twinfast screw,wood screw,Security head screw,self-drilling screw,self-tapping machine screw,Teks screw,auto fasteners,etc.

|

| Special shape parts made by Two Die Three Blow Special Parts Heading Machine |

|

| Wedge anchors made by Two Die Three Blow Special Parts Heading Machine |

|

| Auto mobile exhaust pipe hanging support bolt made by Two Die Three Blow Special Parts Heading Machine |

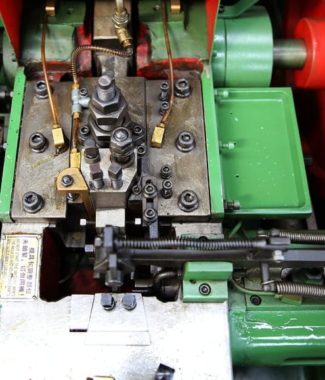

Salient Features of M10*200MM Two Die Three Blow Special Parts Forming Machine

1. The latest design, beautiful appearance, high speed, high efficiency, low energy consumption, easy to operate.

2.Important components, such as bed and sliders are made of high strength and quality castings, and high stability.

3.Guide plate and crankshaft uniform imported high wear resistance alloy steel, and after special treatment, super wearable.

4.The main slide rails design adopts before and after (double track) designed to ensure high-speed impact, stable and reliable.

5.The new type cam and lifter system to ensure the accuracy of first and second punching stability.

6.Some parts adopts machining center to ensure the accuracy and interchangeability of parts.

7.Oil tank multi-stages filtration,forced circulation lubrication system to ensure that the oil filtered and clean to the lubrication points which can extend equipment life.

8.Suitable for making of small screws, precision screws, extra long screws.

Main Standard and optional items for M10*200MM Two Die Three Blow Special Parts Forming Machine

|

|

| Auto checker for forging machine | PKO for forging machine |

|

|

| Screw conveyor for forging machine | Coil stand for forging machine |

Standard accessories of M10*200MM Two Die Three Blow Special Parts Forming Machine

1. One set of trial tools

2. One set of standard hand tools.

3. One set of standard spare parts.

4. One set of control Panel

5. One set of AC motor

6. Inside Lamp