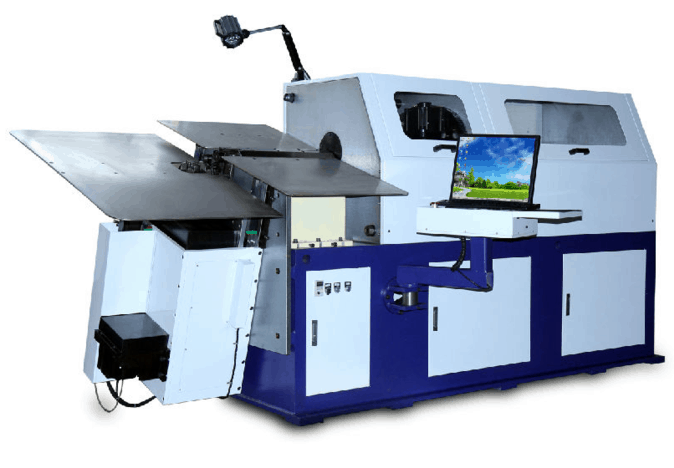

Description

Salient Features of 3D Wire Parts Forming Machine

- Full automatic design with high efficiency.

- Easy to operate and adjustment.

- Advanced PLC control system optional.

Applicable to 3D car seat frame production, sun visor skeleton, car door lock lever, handicraft metal wire, sanitary ware tableware bracket, warehouse cage, shopping trolley and other wire forming equipment

Parameters of 3D Wire Parts Forming Machine

| Model | ASF3D-708 | ASF3D-712 | |

| Wire diameter range | Iron wire | 3.0 – 8.0 mm | 3.0 -12.0 mm |

| Steel wire | 3.0 – 6.0 mm | 3.0 -6.0 mm | |

| Feed line length | UNLIMITED | UNLIMITED | |

| Bending angle | ± 0.02° | ± 0.02° | |

| Maximum wire feed speed | 70 m / min | 70 m / min | |

| Maximum bending speed | 3 turns / sec | 3 turns / sec | |

| Positioning accuracy | ± 0.02° | ± 0.02° | |

| 7- axis performance | Horizontal movement 2.7KW; vertical movement 2KW;feed line 3.8KW; transfer line 2.7KW Cutter 2.7KW; Inner bending knife 2.7KW; outerbending knife 2.7KW |

||

| Installation of electricity | 19.3KVA | 23 KVA | |

| Machine equipment | 320CM long | 320CM long | |

| Width 90 CM | Width 90 CM | ||

| High 150 CM | High 150 CM | ||

| Machine weight | 3000KGS | 3000KGS | |

| Standard equipment : | |||

| (1) Feeding wheel | 4pcs | ||

| (2) Cutter + cutter holder | 1 SET | ||

| (3) Rotating head | 2PCS | ||

| (4) Toolbox | |||

| Optional equipment : | |||

| (1) Wire feeder 500KGS or 1000KGS or 1500 KGS | |||

| (2) Tool TOOLINGS ( customer requirements are optional ) | |||

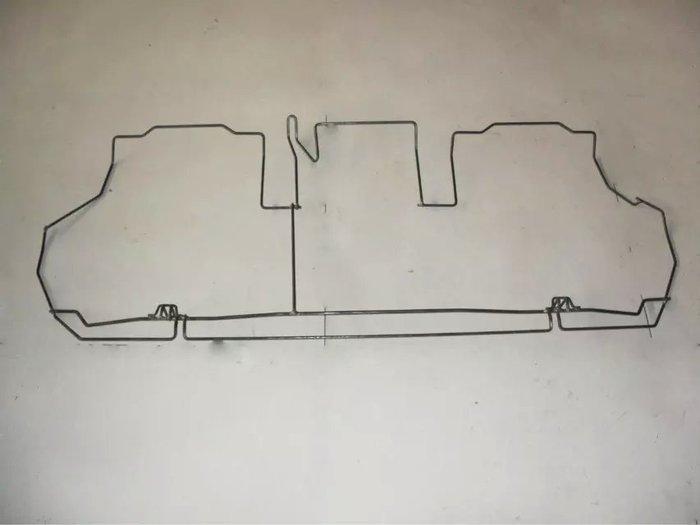

Parts made by 3D Wire Parts Forming Machine1

Parts made by 3D Wire Parts Forming Machine2

Parts made by 3D Wire Parts Forming Machine3