Description

Features of AMR Industrial robot feeding laser welding machine

Fiber transmission laser welding machine is a kind of laser welding equipment which combines high energy laser beam into fiber and transfers long distance. The flexible transmission non-contact welding is applied to the inaccessible parts of the welding, which provides greater flexibility. The laser beam of laser welding machine can realize the time and energy spectrum, and can process multiple beams simultaneously, which provides the condition for more precise welding.

1. The robot welding machine is suitable for large surface space welding. The robot can be operated intelligently, flexibly and reliably.

2. Design professional fixtures according to the appearance of customers’ products.

3. According to the product appearance of customers, multi-station welding operation can be designed to save product installation fixture time and improve production efficiency.

4. Equipped with wobble welding head, the welding seam can be widened through vibration, so that laser welding can be applied more widely. High-efficiency and precise laser welding can be achieved for both large workpiece and workpiece with wide welding seam. And the effect of welding quality is obviously better than that of ordinary welding head. The welding surface is smooth and beautiful, and the welding quality is good.

5. High repetition precision, repeated for many times without error, no consumables, flexible processing and low operation cost.

6. It can replace manual operation and is suitable for some difficult space welding.

Specifications of AMR Industrial robot feeding laser welding machine

| Type | AMR-500 | AMR-800 | AMR-1000 | AMR-1500 | AMR-2200 | AMR-3300 | AMR-4000 | AMR-6000 |

| Laser power | 500W | 800W | 1000W | 1500W | 2200W | 3300W | 4000W | 6000W |

| Working mode | Continuous or short continuous | |||||||

| optical maser wave length | 1070nm-1080nm | 1080nm±5% | ||||||

| Laser stability | ±2% | |||||||

| Laser weight | 20kg | 25kg | 28kg | 40kg | 45kg | 65kg | 70kg | 85kg |

| Optical fiber diameter | 25um-200um | |||||||

| Light spot size | φ0.05-0.2mm | φ0.05-0.2mm | ||||||

| Positioning way | Red light +CCD camera surveillance system | |||||||

| Recommended welding depth | 0.05-1mm Visual materials | 0.1-1.5mm Visual materials | 0.1-2mm Visual materials | 0.1-2.2mm Visual materials | 0.2-2.5mm Visual materials | 0.3-3.5mm Visual materials | 0.5-4mm Visual materials | 1-.5mm Visual materials |

| Fiber length | 10 meters (customizable) | |||||||

| Laser consumes power | ≤3KW | ≤4KW | ≤4.5KW | ≤6KW | ≤8.8KW | ≤13.5KW | ≤16KW | ≤25KW |

| Laser output focal length | 80mm/100mm/120mm/200mm | |||||||

| Laser cooling | Water cooled | |||||||

| Demand for electricity | 380V±10%/50Hz | |||||||

| Control system | CNC or PLC | |||||||

| Shielding gas | Nitrogen or argon | |||||||

| Working temperature | 10-40℃ | |||||||

| Spectral pattern | (time or energy) up to 4 emission | |||||||

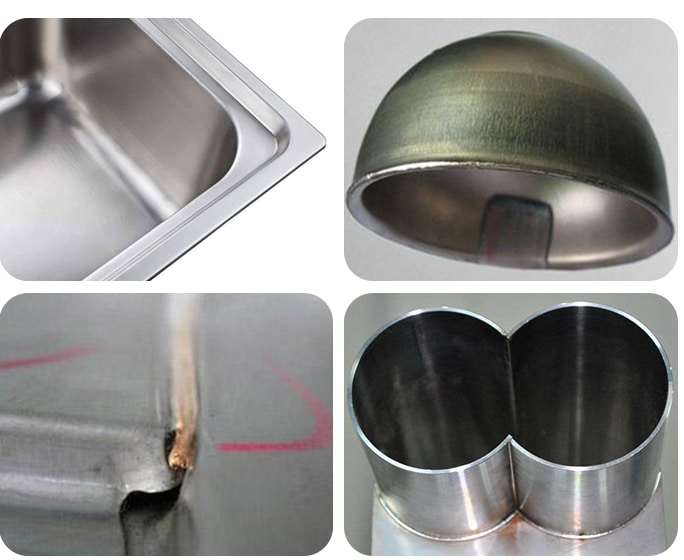

Welded Samples of AMR Industrial robot feeding laser welding machine

Parts welded by AMR Continuous automatic feeding laser welding machine

Welded samples by AMR Industrial robot feeding laser welding machine