Description

Salient Features of AM1808 CNC centerless grinding machine

*Guide wheel adopts servo motor drive and transmission, can achieve stepless speed.

*The feed of the guide wheel frame is fed by roller rod servo motor , and the feed guide rail is plastic coated guide rail.

*The guide wheel main spindle adopts double row cylindrical roller bearing structure or traditional dynamic pressure tile structure , and the guide wheel has a double support structure.

*The grinding wheel has a double supporting structure, and the grinding wheel spindle adopts a dynamic and static pressure structure.

*The machine tool adopts grinding wheel frame fix design, and the guide wheel frame is movable layout.

Main use and application scope of AM1808 CNC centerless grinding machine

Mainly suitable for semi-automatic or fully automatic operation of various step, cone and cylindrical rotating surfaces on metal parts.The machine is suitable for small batch and batch production applications.

Working accuracy :

Roughness : Ra 0.16 um

Cylindricity : 0.002mm

Roundness : 0.001mm

AM1808 CNC centerless grinding machine specifications:

Machine specifications:

| AMC-18 | AMC-18S | AMC-18A | AMC-18AS | AMC-18B | AMC-18BS | |

| Standard workbench work diameter | Ø1 ~ Ø50 mm | |||||

| Special workbench work diameter | Ø40 ~ Ø100 mm | |||||

| Grinding wheel size (outer diameter x width x inner diameter) | Ø455 x 205 x Ø228.6 | Ø455 x 255 x Ø228.6 | Ø455 x 305 x Ø228.6 | |||

| Adjust wheel size (outer diameter x width x inner diameter) | Ø255 x 205 x Ø111.2 | Ø255 x 255 x Ø111.2 | Ø255 x 305 x Ø111.2 | |||

| Grinding wheel speed | 1500 RPM | |||||

| Adjust wheel speed | 13-316 RPM (10 paragraphs) |

10-250 RPM Stepless speed change |

13-316 RPM (10 paragraphs) |

10-250 RPM Stepless speed change |

13-316 RPM (10 paragraphs) |

10-250 RPM Stepless speed change |

| Wheel drive motor | 15 HP | 15 HP | 20 HP | |||

| Adjustment wheel drive motor | 2 HP | 4HP servo motor | 2 HP | 4HP servo motor | 2 HP | 5HP servo motor |

| Hydraulic pump drive motor | 1 HP | |||||

| Cooling pump drive motor | 1/4 HP | 1/2 HP | ||||

| Adjust wheel feed hand wheel | 3.5 mm per revolution (Rev) 0.05 mm per gra (Gra) | |||||

| Adjustment wheel fine adjustment hand wheel | 0.1 mm per revolution per painting (Rev) 0.001 mm (Gra) | |||||

| Worktable feed hand wheel | 9 mm (Rev) per revolution 0.05 mm (Gra) | |||||

| Workbench fine-tuning handwheel | 0.2 mm (Rev) per revolution 0.001 mm per gra (Gra) | |||||

| Trimming the hand wheel | 2 mm per revolution (Rev) 0.01 mm per gra (Gra) | |||||

| Adjust wheel tilt angle | +5° ~ -3° | |||||

| Adjust wheel rotation angle | ±5° | |||||

| Mechanical size (L x W x H) | 2300 x 2000 x 1530 mm | |||||

| Net weight / gross weight | 2800 kgs / 3100 kgs | 2900 kgs / 3200 kgs | 3000 kgs / 3300 kgs | |||

| Packing size (L x W x H) | 3200 x 1400 x 1900 mm | |||||

| AM-1808S | AM-1810S | |

| Standard workbench work diameter | Ø1 ~ Ø50 mm Ø1 ~ Ø50 mm | |

| Special workbench work diameter | Ø50 ~ Ø90 mm Ø50 ~ Ø90 mm | |

| Grinding wheel size (outer diameter x width x inner diameter) | Ø455 x 205x Ø228.6mm | |

| Adjust wheel size (outer diameter x width x inner diameter) | Ø225 x 205 x Ø111.2mm | |

| Grinding wheel speed | 1450 RPM | |

| Adjust wheel speed | 0 – 300 RPM stepless speed change | 0 – 300 RPM stepless speed change |

| Wheel drive motor | 15 HP | |

| Adjustment wheel drive motor | 3Kw | 3kw |

| Hydraulic pump drive motor | 2HP | |

| Cooling pump drive motor | 1/4 HP | |

| Adjust the wheel feed scale | 3.5 mm per revolution (Rev) 0.05 mm per gra (Gra) | |

| Adjust wheel feed fine adjustment scale | 0.1 mm (Rev) per revolution 0.001 mm per gra (Gra) | |

| Worktable cutting scale | 9 mm (Rev) per revolution 0.05 mm (Gra) | |

| Workbench fine-tuning scale | 0.2 mm (Rev) per revolution 0.001 mm per gra (Gra) | |

| Trimming infeed scale | 2 mm per revolution (Rev) 0.01 mm per gra (Gra) | |

| Adjust wheel tilt angle | +5° ~ -3° | |

| Adjust wheel rotation angle | ±5° | |

| Mechanical size (LxWxH) | 2265 x 1900 x 1650 mm | |

| Net weight / gross weight | 1600 kgs / 1750 kgs | |

| Packing size (L x W x H) | 2400 x 2100 x 1800 mm | |

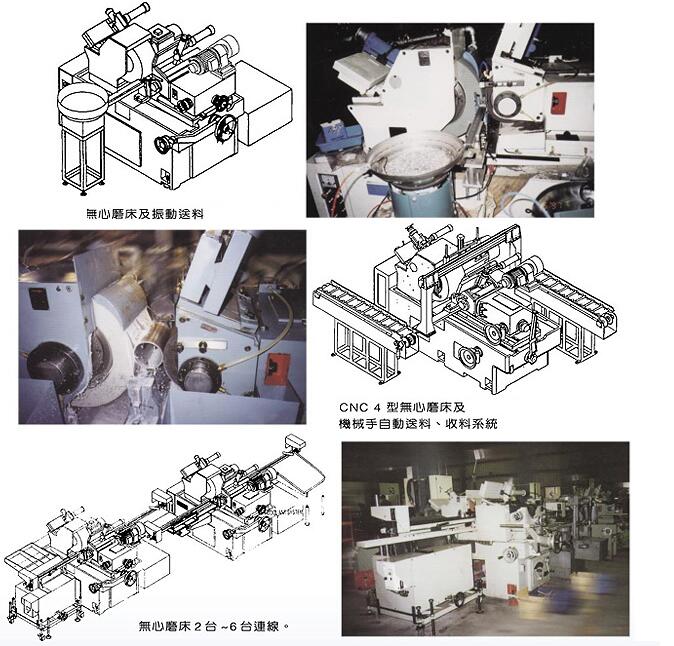

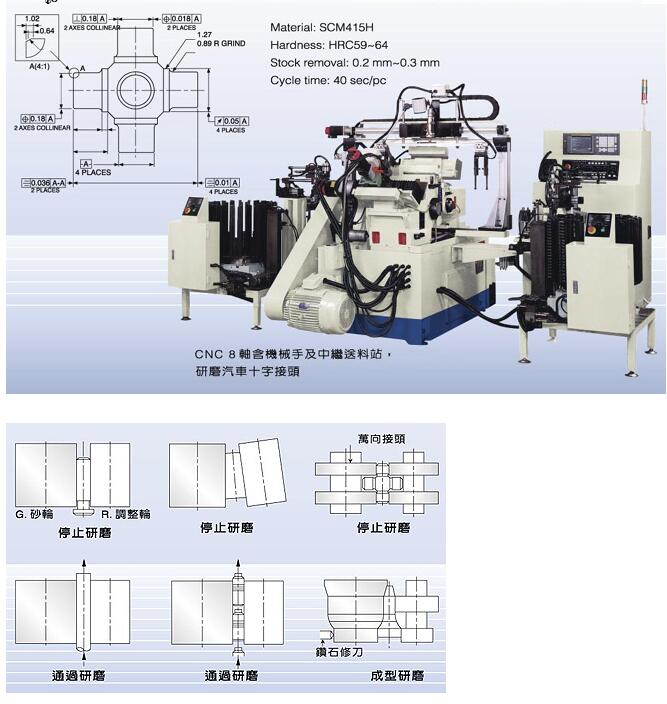

Application of of AM1206 single axle NC centerless grinding machine1

Application of of AM1206 single axle NC centerless grinding machine2

Standard accessories of AM1206 single axle NC centerless grinding machine

1. Grinding wheel and grinding wheel flange

2. Grinding wheel and grinding wheel flange

3. Pass the standard tool holder and blade

4. Stop the standard tool holder and blade

5. Toolbox and tools

6. Work light

7. Diamond repair knife

8. Passing the safety device

9. Flange puller

10. Horizontal screws and horizontal plates

11. Through the feed trough

Optional accessories of AM1206 single axle NC centerless grinding machine

1. Iron separator

2. Paper tape filter

3. Hydraulic separator

4. Material return device

5. Forming and finishing device

6. Long object feeding rack

7. Up and down feeding rack

8. By grinding automatic receiving device

9. By grinding automatic feeding device

10.Vibration feeding tray

11. Taper automatic forming grinding device

12. Stop forming automatic grinding device

13. Balance bar

14. Balance station

15. Out-of-line working outside diameter sensing measurement system

16. Grinding wheel automatic balance system

17. Oil temperature radiator

18. Rotary grinding wheel dressing device

19. Grinding wheel hanger

20. Grinding wheel dynamic balance corrector

21. Oil mist recovery machine