Description

Features of AMH optical fiber laser welding machine with CCD camera

Fiber transmission laser welding machine is a kind of laser welding equipment which combines high energy laser beam into fiber and transfers long distance. The flexible transmission non-contact welding is applied to the inaccessible parts of the welding, which provides greater flexibility. The laser beam of laser welding machine can realize the time and energy spectrum, and can process multiple beams simultaneously, which provides the condition for more precise welding.

1、The optical fiber transmission laser welding machine selects the CCD camera monitoring system, which is convenient for observation and accurate positioning.

2、The energy distribution of the welding spot of the optical fiber laser welding machine is uniform and has the characteristic of the welding characteristic.

3、Laser welding can achieve spot welding, butt welding,superposition welding and sealing welding for thin wall materials and precision parts.

4、The quality of the weld is high and beautiful and has no hole. The toughness of the material after welding is at least equal to the parent material.

5、Four ball screw table, control system adopts imported servo,optional rotary table can realize direct welding, spot welding,circumferential welding automatic welding etc..

6、The energy distribution of the welding spot in the optical fiber laser welding machine is uniform, and it has the best spot forwelding characteristics.

7、Fiber laser welding machine is suitable for various complex welding, spot welding and seam welding of various devices, less than 1mm sheet.

8、The optical fiber transmission laser welding machine adopts the British imported ceramic cavity, which has corrosion resistance, high temperature resistance and the life span of the cavity (3-5), and the life of the xenon lamp is more than 2 million times.

9、It can customize the special automatic chemical equipment fixture to realize the mass production of the products.

Specifications of AMH optical fiber laser welding machine with CCD camera

| Model | AMH-300W | AMH-400W | AMH-500W |

| Laser wavelength | 1064nm | 1064nm | 1064nm |

| Output optical power | 300W | 400W | 500W |

| Maximum pulse energy | 90J | 90J | 90J |

| Maximum peak power | 6.5KW | 7KW | 8KW |

| Pulse width | 0.3-15ms | 0.3-15ms | 0.3-15ms |

| Solder joint size | 0.4-2mm | 0.4-2mm | 0.4-2mm |

| Pulse repetition frequency | 1—100HZ | 1—100HZ | 1—100HZ |

| Weld penetration | <0.8mm | <2mm | <2.5mm |

| Welding depth | <0.8mm | <2mm | <2.5mm |

| Weld penetration (pure aluminum) | <0.4mm | <1.2mm | <1.7mm |

| Welding depth (copper) | <0.4mm | <1.2mm | <1.7mm |

| Weld penetration (brass) | <0.4mm | <1.2mm | <1.7mm |

| Weld penetration (nickel) | <0.4mm | <1.2mm | <1.7mm |

| Unit time continuous(1s) | 200ms/s | 200ms/s | 200ms/s |

| Light splitting method | Precision energy or high speed time spectrophotometry | ||

| Closed loop feedback | Real-time control of power negative feedback with arbitrary waveform | ||

| Energy volatility | <±3% | ||

| Fiber separation number | ≤4(Standard single light path) | ||

| Aiming positioning method | Laser diode red light indicates CCD selection | ||

| Cooling mode | External chiller (with internal circulation) | ||

| Equipment power consumption | 16KW | 18KW | 21KW |

| Power requirements | AC380V±15% 50/60Hz | AC380V±15% 50/60Hz | AC380V±15% 50/60Hz |

| Mainframe size | 1460*660*1080mm | 1460*660*1080mm | 1460*660*1080mm |

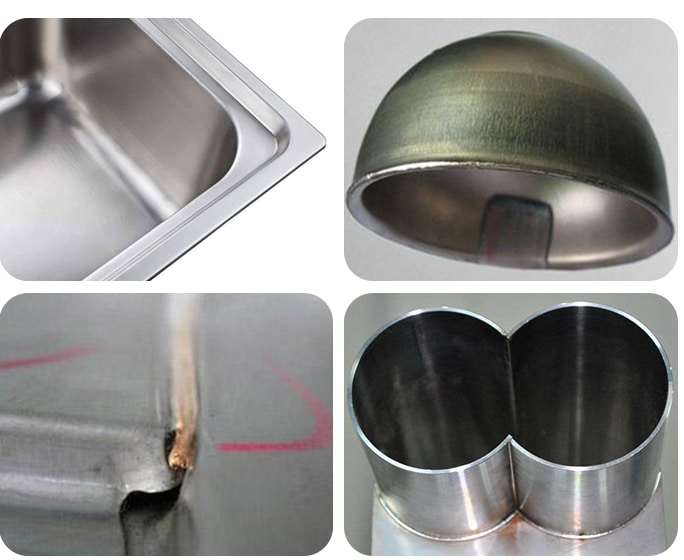

Welded Samples of AMH optical fiber laser welding machine with CCD camera

Welding parts by AMH optical fiber laser welding machine with CCD camera

Parts welded by AMR Continuous automatic feeding laser welding machine

Welded samples by AMR Industrial robot feeding laser welding machine