Description

Features of AMY hard light path pulse laser welding machine

Fiber transmission laser welding machine is a kind of laser welding equipment which combines high energy laser beam into fiber and transfers long distance. The flexible transmission non-contact welding is applied to the inaccessible parts of the welding, which provides greater flexibility. The laser beam of laser welding machine can realize the time and energy spectrum, and can process multiple beams simultaneously, which provides the condition for more precise welding.

1. The hard-light laser welding machine is equipped with CCD camera monitoring system for convenient observation and accurate positioning.

2. The energy distribution of welding spot of hard light path laser welding machine is uniform, which has the characteristics of welding equipment.

3. Hard light laser welding can realize spot welding, butt welding, overlaying welding and sealing welding for thin-walled materials and precision parts. The welding quality is high, smooth and beautiful, without pores, and the toughness of the material after welding is at least equal to that of the parent material.

4. Four-dimensional ball screw table, adopting imported servo control system, with optional rotating working table, can realize automatic welding such as spot welding, direct welding and circumferential welding.

5. The energy distribution of welding spot of hard light path laser welding machine is uniform, which has the best spot required for welding characteristics.

6. The hard optical laser welding machine is suitable for various complex welds, spot welding of various devices, and seam welding of thin plates within 1mm.

7. The hard light path laser welding machine adopts the concentrated cavity of ceramic imported from Britain, which is resistant to corrosion, high temperature and cavity life (3-5) years, and xenon lamp life over 2 million times. Can be customized special automatic chemical equipment jig, to achieve mass production of products.

Specifications of AMY hard light path pulse laser welding machine

| Type | AMY-300W | AMY-400W | AMY-500W |

| Optical maser wavelength | 1064nm | 1064nm | 1064nm |

| Output power | 300W | 400W | 500W |

| Maximum pulse energy | 90J | 90J | 90J |

| Maximum peak power | 6.5KW | 7KW | 8KW |

| Pulse width | 0.3-15ms | 0.3-15ms | 0.3-15ms |

| Globule size | 0.4-2mm | 0.4-2mm | 0.4-2mm |

| Pulse repetition rate | 1—100HZ | 1—100HZ | 1—100HZ |

| Welding penetration (stainless steel 304) | <0.8mm | <2mm | <2.5mm |

| Welding penetration (carbon steel plate) | <0.8mm | <2mm | <2.5mm |

| Welding penetration (pure aluminum) | <0.4mm | <1.2mm | <1.7mm |

| Welding penetration (copper) | <0.4mm | <1.2mm | <1.7mm |

| Welding penetration (brass) | <0.4mm | <1.2mm | <1.7mm |

| Welding penetration (nickel) | <0.4mm | <1.2mm | <1.7mm |

| Continuous pulse width per unit time (1s) | 200ms/s | 200ms/s | 200ms/s |

| Spectroscopic methods | Up to one way | ||

| Closed loop feedback control | Real-time control of power negative feedback with arbitrary waveform | ||

| Energy fluctuation | <±3% | ||

| Aiming mode | Laser diode red light indicates CCD selection | ||

| Cooling way | External chiller (with internal circulation) | ||

| Power consumption | 16KW | 18KW | 21KW |

| Power Supply | AC380V±15% 50/60Hz | AC380V±15% 50/60Hz | AC380V±15% 50/60Hz |

| Size of Host Machine | 1850*660*1900mm | 1850*660*1900mm | 1850*660*1900mm |

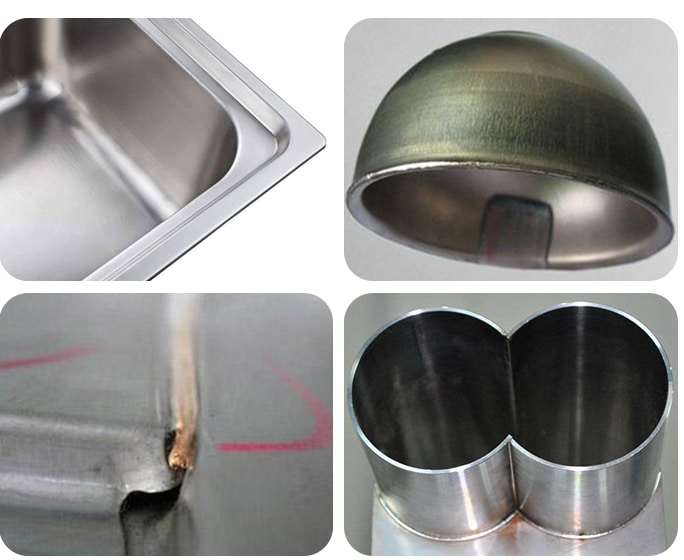

Welded Samples of AMY hard light path pulse laser welding machine

Weld parts by AMY hard light path pulse laser welding machine

Parts welded by AMR Continuous automatic feeding laser welding machine

Welded samples by AMR Industrial robot feeding laser welding machine