Description

Specifications of Horizontal forging stations bolt hot heading machine with manipulator transfer

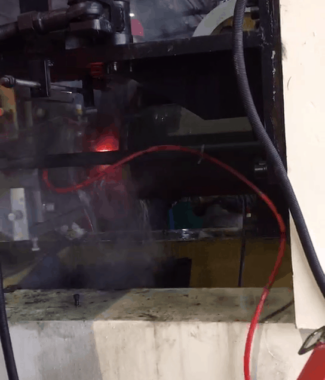

There are two types of heating methods, one is flammable gas heating, and the other is medium frequency induction furnace heating.

| model | Part weight g | Speed Pcs/min | Motor power kw | Medium frequency furnace power kw | Machine weight kg | Machine size L*W*H |

| AW-06 | 30 | 70 | 4 | 50 | 2500 | 2150X1100X1100 |

| AW-08 | 50 | 70 | 7.5 | 60 | 5000 | 4200X1500X1450 |

| AW-10 | 100 | 70 | 15 | 80 | 8000 | 4900X1850X1820 |

| AW-12 | 120 | 70 | 18.5 | 100 | 10000 | 5000X1900X1800 |

| AW-16 | 160 | 65 | twenty two | 120 | 12000 | 5600X1900X1950 |

| AW-20 | 200 | 60 | 30 | 150 | 15000 | 5800X1950X1900 |

| AW-30 | 250 | 60 | 30 | 200 | 18000 | 5800X2000X1900 |

Application scope of Horizontal forging stations bolt hot heading machine with manipulator transfer

The automatic hot forming machine is an efficient automatic machine tool for producing complex blanks. The production raw materials are ø15-ø30 copper rods, and after a series of processes such as automatic heating, cutting, stamping and material discharging, the blanks are finally punched out.

Applicable production parts: caliper, copper core, air conditioning nut, valve body, communication valve handwheel, plumbing joint, copper hex nut, copper nut, inner thread elbow, outer thread elbow, connection joint elbow, valve core, copper joint, joint caps, single joints, forging nuts, air conditioning check valves, spools nozzle caps, valves, caps, plugs, etc.

Features of Horizontal forging stations bolt hot heading machine with manipulator transfer

The Brass fasteners and pipeline parts hot forging machine forging mold die open design,Including medium frequency electric heating device, feeding device, cutting device, main slider and electric drive mechanism. This equipment can be used for local continuous heating (600 °C-800 °C), continuous cutting, continuous upsetting, and the product can be formed at one time, which reduces the number of high-strength screw products that can be tempered and cooled. It solves the processing problem of complex parts, can continuously produce, improve the efficiency, and through the local heating of the wire, the long product which can not be produced by the whole heating can greatly improve the service life of the mold.

Automatic hot stamping machine: It adopts medium frequency furnace heating, using the upsetting pressure of the machine, automatic feeding, automatic cutting, automatic heating, automatic stamping and automatic blanking. The product can be molded in the mold at one time, and irregular parts such as a spherical shape, a hexagonal shape, and a large flat head can be produced. After adopting this technology, the material can be reduced, the cost can be reduced, the product can be molded once, the process can be reduced, the deep hole and the porous part can be made, the complicated problem of the part can be solved, and the continuous production can improve the efficiency. This equipment is the ideal equipment to solve the cold rolling process, and it is the upgrade and replacement of the red hot rolling process.

● Production efficiency: 5 to 6 times of the punching machine, depending on the product, it can reach 35~70 per minute.

● User: One person operation, saving 5 people compared with traditional punching machine

● Safety: fully automatic production, safe and reliable, no work accidents

● Production cost: one 60-100kw medium frequency heating furnace, one main motor, saving about 30%

● Pass rate: 98% of the product is qualified higher than press.