Description

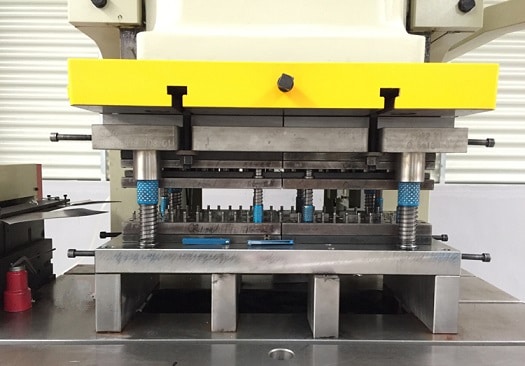

Video of M8 Hex Nut Sleeve Anchor sleeve high speed Progressive stamping tooling

6MM wedge anchor clip sheet metal Progressive pressing die

| Line | Description | Parameters |

|---|---|---|

| 1 | Design: | As per standard wedge anchor clips design, customer design and specific requirements |

| 2 | Accept drawing format: | .pdf/.jpg / .dwg / .igs / .stp etc.. |

| 3 | Material: | carbon steel, alloy steel, stainless steel, high-speed steel and etc. |

| 4 | Size: | Accordng to the drawings or Customized drawing |

| 5 | Material standard: | If there is no any specially requirement, we often sugguest our customer to try the equivalent China National (GB) standard material that our engineering team proposes which to be properly converted from ANSI, ASTM, SAE, EN, DIN, BS, JIS, and etc., to contribute the material cost control. If it is necessary to use exact designated material no., it is also possible choice. |

| 6 | Components and types: | sheet metal high speed Progressive stamping die,blanking die,trimming die,punching die,flanging die,bending die, drawing die and etc. |

| 7 | Fuctions and usage: | -blanking-piercing-cutting off-trimming-stretching-deep drawing-flanging-bending-plunge-bulging-finishing |

Sleeve anchor clip sheet metal Progressive stamping die

Principle of M8 Hex Nut Sleeve Anchor sleeve high speed Progressive stamping tooling

Progressive Die Stamping is a demanding method of working with metal that can encompass not just “stamping”, but punching, bending and several other ways of modifying various types and grades of metal raw material, combined with an automatic feeding system.

Progressive stamping dies are made of tool steel to withstand the high shock loading involved, retain the necessary sharp cutting edge, and resist any abrasion forces involved. The progressive stamping die is placed into a reciprocating stamping press. As the press moves up, the top die moves with it, which allows the material to feed. When the press moves down, the die closes and performs the progressive stamping die operation. With each stroke of the press, a completed part is removed from the die.

A feeding system pushes a strip of metal as it unrolls from a coil through all of the stations of a progressive stamping die. Each station performs one or more operations until a finished part is made. Additional work is done in each “station” of the progressive stamping die. The strip must be advanced very precisely so that it aligns within a few thousandths of an inch as it moves from station to station. Bullet shaped or conical “pilots” enter previously pierced round holes in the strip to assure this alignment since the feeding mechanism usually cannot provide the necessary precision in feed length. The final station of the progressive stamping die is a cutoff operation, which separates the finished part from the carrying web. The carrying web, along with material that is punched away are knocked down or out of the dies, and then ejected from the die set. Scrap material is transferred to bins to be recycled.

The number of features determines what tooling and how many stations the progressive stamping die will have. Many companies advise keeping the number of features as simple as possible to keep the cost of the progressive stamping die tooling to a minimum. They may want extra clearance for the punch, which could result in another station. It can also be problematic to have narrow cuts and protrusions. This is not a practical approach as the part needed may have features that need to be close together. The progressive stamping die design should not be a reflection of the limitations of the designer or the shop.

Such “problematic” situations require the most exacting design of the progressive stamping die itself. Bahrs expert tool and die makers see these potential problems, but can also ‘see and think’ about how to resolve them through masterful progressive stamping die design to produce parts that meet the need. As a first critical aspect of tool design, the progressive stamping tool and die designers at Bahrs Die & Stamping gain a clear understanding of the part and intended end use application.

Only time, training and experience in the design of tooling and progressive stamping dies can supply this critical ‘forward thinking’ necessary for a progressive stamping die to be designed that is exact and meets the need.

Bahrs Die & Stamping has been producing quality custom progressive stamping dies and metal stampings for 75 years. It is our goal to supply the finest quality progressive stamping dies and tooling at very competitive prices without sacrificing critical aspects of progressive stamping die and tool design and function. We design, build and maintain our own progressive stamping dies, tooling and fixtures in house giving us control over all aspects of the manufacturing process.

The owners of Bahrs Die & Stamping are designers and engineers with over 60 years of experience custom designing Progressive Stamping Dies for a wide variety of applications.

The Benefits of High Volume Progressive Stamping

With progressive metal stamping, ESI eliminates those hassles and inefficiencies. A progressive stamping tool features a number of stations, each with a unique function.

As strip metal feeds through a progressive stamping press, unrolling steadily from a coil, each station in the tool performs a different cut, punch, or bend.

The actions of each successive station add onto the work of the previous stations, resulting in a completed part.

For very simple parts, progressive die metal stamping may not be the best option. But there are many scenarios in which progressive stamping is ideal. Advantages of progressive stamping include:

Speed: With a continual feed of material, progressive stamping machines operate at extremely high speeds of hundreds of parts per minute and with minimal downtime.

Speed: With a continual feed of material, progressive stamping machines operate at extremely high speeds of hundreds of parts per minute and with minimal downtime.- Low Labor Cost: One operator can oversee many machines that run unattended due to electronic monitoring embedded in our custom tooling.

- Run Length: The same continual feed of material that provides progressive stamping it’s speed also allows for long production runs. More production time between material changes means more completed parts in shorter amounts of time.

- Minimal Scrap: Scrap metal is inevitable in any manufacturing process, but it is minimized by optimized tool design of progressive stamping.

- Quick Setup: Multiple setups, tool changes, and die changes are required to produce complex parts with conventional short-run stamping methods; only one setup is required to produce completed parts using progressive stamping.

- Complex Geometry: Creation of parts with complex geometries is possible by the building nature of the die stations in a progressive tool.

- High Repeatability: The dies of a progressive stamper are hard tooled. They can withstand the high volume runs of progressive stamping without degrading, maintaining the high quality of the parts produced.

- Low Part Cost: These factors combine to reduce the per part cost of parts manufactured by progressive stamping.

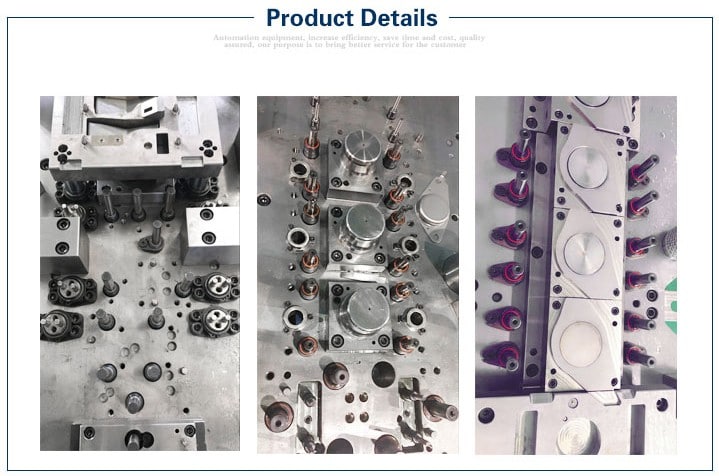

wedge anchor clip sheet metal Progressive stamping die details

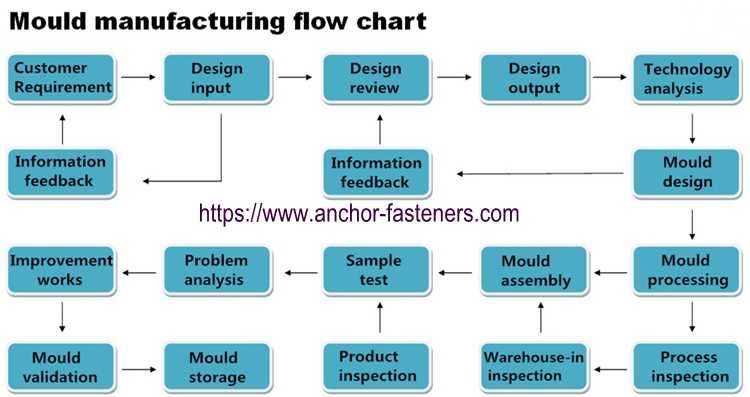

wedge anchor clip sheet metal Progressive stamping die making process

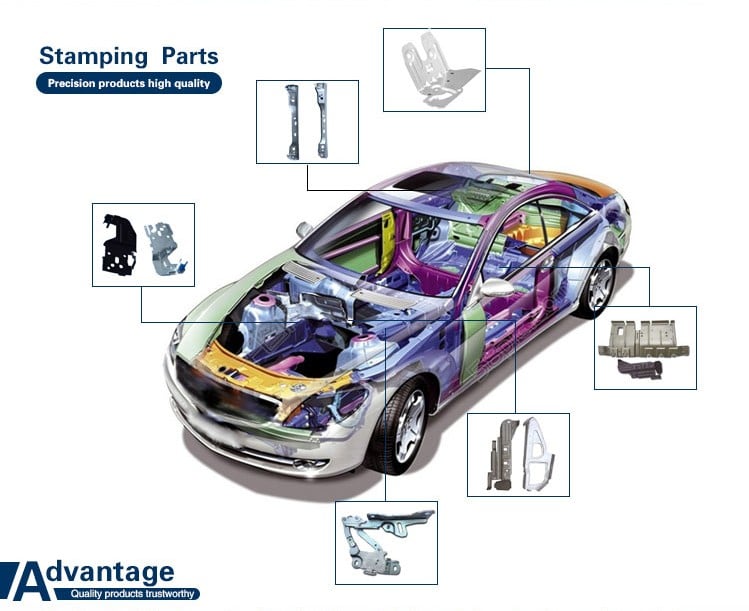

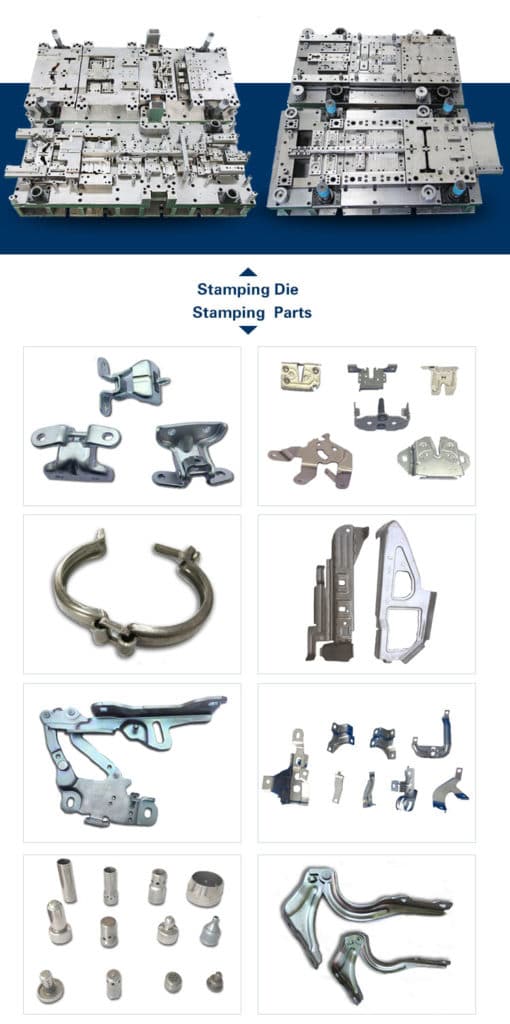

sheet metal Progressive stamping die stamping automotive parts

sheet metal Progressive stamping die and stamping auto motive part

wedge anchor clip sheet metal Progressive stamping die storage

PROGRESSIVE DIE VS. TRANSFER DIE STAMPING

The two types of die stamping processes you may encounter are progressive die stamping and transfer die stamping. What do these different types of stamping entail, and what are the advantages and disadvantages of each? What types of applications are most common to transfer die vs. progressive die stamping and vice versa?

WHAT IS PROGRESSIVE DIE STAMPING?

In progressive die stamping, a coil of metal is fed through a machine that consists of a series of stamping stations that perform simultaneous operations. The metal strip moves through the drawing process, with each progressive die station altering the configuration on the metal from the previous station. Once the metal has gone through the entire machine and all the stamping stations, the piece will be complete.

WHAT ARE THE ADVANTAGES OF PROGRESSIVE DIE STAMPING?

Progressive die stamping is well-suited to operations needing to produce many small pieces quickly, since you can perform multiple cutting and forming operations simultaneously. This combining of operations can also save on costs, although you will have to pay for permanent tool steel die sets. Progressive die stamping can also allow you to maintain close tolerances if you have the right tools.

WHAT APPLICATIONS TYPICALLY USE PROGRESSIVE DIE STAMPING?

You can find progressive die stamping in a variety of industries, including automotive, locomotive, heavy trucks and RVs, medical, electronics and agriculture.

WHAT IS TRANSFER DIE STAMPING?

In transfer die stamping, rather than feed the metal part through a series of stations, a mechanical transport system transfers the part from station to station. The transfer die can be a single die or part of several dies lined up in a row. Transfer die stamping is used to perform operations on the part free from the strip.

WHAT ARE THE ADVANTAGES OF TRANSFER DIE STAMPING?

Transfer die stamping tends to be more economical than progressive die stamping. It is also much more versatile than progressive die stamping. If your part has features like cut-outs, pierced holes, ribs, knurls or threading, you can use transfer die stamping to work these into regular press operations so that you don’t need secondary operations at added cost.

WHAT APPLICATIONS TYPICALLY USE TRANSFER DIE STAMPING?

You will use transfer die stamping when you have large parts you need to transfer between multiple presses to complete them, such as shells, tube applications, frames and structural components. You can find transfer die stamping in all the industries where you find progressive die stamping. It all depends on the specific type of part you are stamping and your requirements for that part.