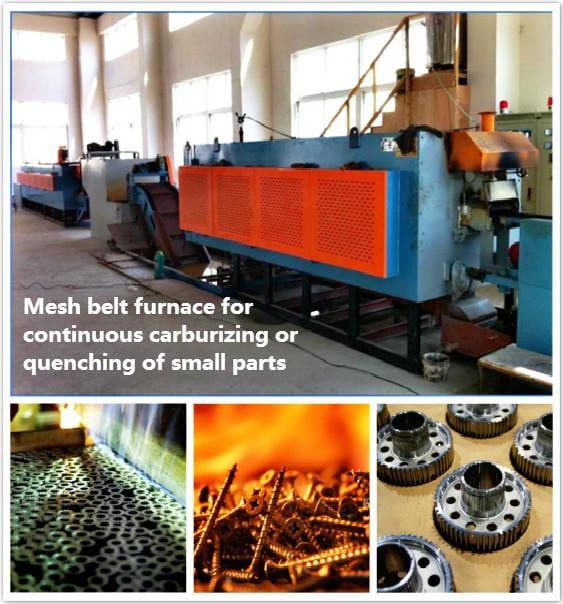

Description

Introduction of Electric Heating Annealing Heat Treatment Furnace

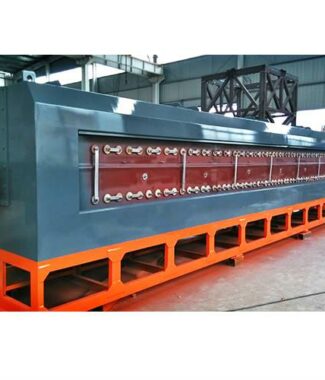

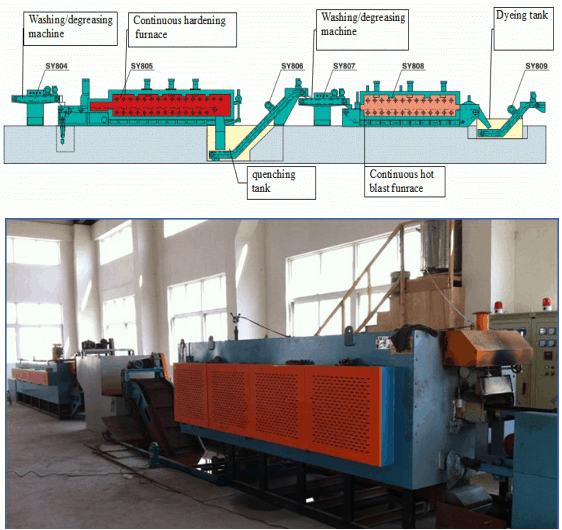

The Electric Heating Quenching Heat Treatment Furnace consists of work parts chain lifting type /magnetic material feeding type/vibrating type loading machine-front decreasing washing tank/pre-washing machine-Continuous Mesh-belt Conveyor & Gas controlled quenching/hardening/carburizing furnace-Quenching cooling oil(water) tank-Rear degreasing & washing tank/ rear washing machine-Continuous mesh belt conveyor tempering furnace-Double-layer dyeing tank(optional)-Automatic furnace operation and temperature control cabinet, it can automatically complete the carburizing, quenching, tempering and blacking dyeing process. Key parts used imported famous brands products, manufacturing and assembly ability reach the domestic advanced level.

Available Processes: carburizing , quenching,tempering,dyeing,Austemper, martemper, salt quenching, None oxy quenching

Protective Gas: according to process required

Parts to be treated: Such as Standard parts, Hand tools, Hardware, automatic small parts, bicycle parts,Bearing, bolt, nut, chain, knuckle, clip etc

Heating Mode: Electricity

Product Parameter of Electric Heating Annealing Heat Treatment Furnace

| Model Type | Main Furnace Power(KW) | Complete Line Power | Rated Temperature(℃) | TemperatureControl Zone | Carbon Control Zone | Effective Working SizeLxWxH(mm) | Quenching Production Capacity(kg/h) | Carburizing Production Capacity(kg/h) |

| NAPM60-9 | 60KW | 95KW | 950 | 3 | 1 | 2400×500×80 | 100 | 80 |

| NAPM80-9 | 80KW | 135KW | 950 | 3 | 1 | 3200×500×80 | 180 | 140 |

| NAPM 100-9 | 100KW | 165KW | 950 | 3 | 1 | 4100×500×80 | 200 | 160 |

| NAPM 140-9 | 140KW | 240KW | 950 | 4 | 1 | 4400×600×80 | 250 | 200 |

| NAPM 170-9 | 170KW | 280KW | 950 | 5 | 2 | 6700×500×80 | 350 | 300 |

| NAPM 180-9 | 180KW | 290KW | 950 | 5 | 2 | 5800×600×80 | 380 | 320 |

| NAPM 200-9 | 200KW | 320KW | 950 | 5 | 2 | 6700×600×80 | 420 | 360 |

| NAPM 240-9 | 240KW | 380KW | 950 | 5 | 2 | 6700×800×80 | 500 | 420 |

| Model | Treating Capacity Per/Hour to Middle or High Carbon Steel (kg) |

Treating Capacity Per/Month to Middle or High Carbon Steel (Tons) |

Treating Capacity Per/Hour to Low Carbon Steel (kg) |

Treating Capacity Per/Month to Low Carbon Steel (Tons) |

Whole-set Total Power Output (kw) |

Whole-set Power Used Middle Carbon 85% Low Carbon 70% (kw) |

Whole-set Total Length (kw) |

| NAPM805-A | 124-138 | 77-86 | 48-69 | 30-43 | 183-177 | 150/123 | 25495 |

| NAPM805-1 | 198-220 | 123-138 | 84-120 | 52-75 | 218-203 | 173/142 | 27995 |

| NAPM805-2 | 352-385 | 220-242 | 204-240 | 127-150 | 320-290 | 247/203 | 31495 |

| NAPM805-3 | 414-483 | 259-299 | 313-350 | 195-218 | 393-353 | 300/247 | 31995 |

| NAPM805-4 | 506-572 | 316-358 | 413-463 | 258-289 | 464-439 | 373/307 | 31995 |

| NAPM805-5 | 720-780 | 450-486 | 546-598 | 341-373 | 543-513 | 436/359 | 35995 |

| NAPM805-6 | 1000-1100 | 624-686 | 833-917 | 520-572 | 655-615 | 522/430 | 39430 |

| NAPM805-6S | 1200-1320 | 749-824 | 999-1100 | 624-686 | 749-688 | 636/481 | 43430 |

| NAPM805-7 | 1250-1375 | 780-858 | 1040-1146 | 649-715 | 759-683 | 645/478 | 39430 |

| NAPM805-7S | 1500-1650 | 936-1030 | 1249-1375 | 779-858 | 886-797 | 753/558 | 43430 |

※Monthly (26 working days tons)

Features of Electric Heating Annealing Heat Treatment Furnace

1)Stable quality and durable performance and output.

2)Efficient electric energy saving and save the production cost.

3)Excellent design and quality to improve the life of the heat radiant tube lift and make it easily to maintenance and replace.

4)Widely used in various industries of domestic and abroad.

5)Furnace lining is mainly made of light fiber which has the characteristics of fast brickwork and small volume.

6)The whole furnace line with automatic and reliable control system, alarm system and safety system.

Parts treated by Electric Heating Continuous Mesh Belt Quenching and Tempering Heat Treatment Furnace