Description

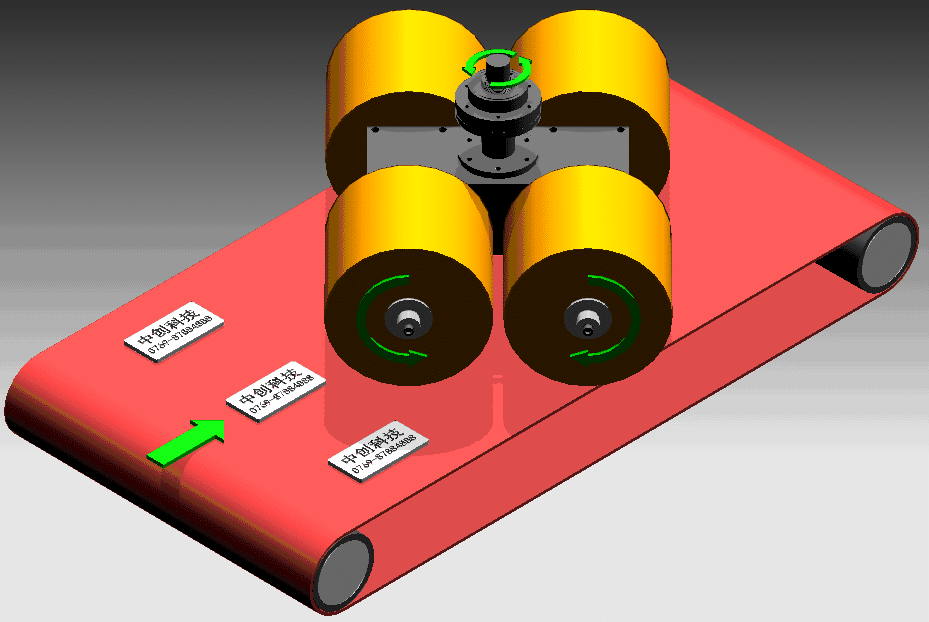

Principle and application of Flat surface deburring machine

Number of sand frames 2

Processing width (mm) 1300

Processing thickness (mm) 1-60

Belt specifications (circumference * width) 2100mm * 1300mm

Minimum processing length 250mm

Pipeline feed rate (frequency conversion) 0.5-1.9 m / min

Belt line speed 13.5 m / sec

Whether wet or dry is

Is it possible to select magnetic field adsorption?

Machine outside dimensions (mm) 2000*1900*2150

Total power (kw) 33

Weight (T) 2.3

Magnetic universal chamfer deburring machine by using the universal grinding wheel to rotate alternately at high speed, the sanding wheel slid over the working angle surface, and the burrs are evenly removed and evenly chamfered. The main function is polishing the position of chamfer, and the friction on the flat surface is very small. For example, the coated sheet metal parts are burred after laser cutting or stamping, and are deburred through the machine while chamfering. The size of the R angle can be adjusted as needed without damaging the coated film.

Principle of Magnetic universal chamfer deburring machine

1. Suitable for deburring of metal parts after laser cutting, CNC or ordinary punching, die-casting, wire drawing, Such as high-quality processing parts such as iron, steel, stainless steel, copper, aluminum, zinc, magnesium.

2. For irregular parts, all the holes on the special-shaped parts, including the slit corners, can be deburred and chamfered evenly.

Features of Magnetic universal chamfer deburring machine

1. Uniform removal of the same surface burr, any external hole size and hole sahpe burr processed and high-end deburring quality that cannot be replaced by manual or equipment.

2. Low cost, the main shaft adopts 25mm aperture of general consumables, and the consumables have no binding and limitations.

3. Processing speed is fast, according to the processing efficiency South Africa, optional single or multi-unit models, processing line speed is adjustable from 0.1-28/m per minute.

4. Variable frequency adjustment to meet various processing needs.

5. Uniform processing, while not hurting the positive plane, does not hurt the protective film.

6. The operation is simple, the product is placed on the conveyor belt and automatically sent out through the machine.

7. Cutting friction force digital display, frequency, and conveying speed are digitally simple and clear.

8. The finished product is not deformed after processing and has high efficiency, which does not affect the dimensional accuracy and thickness.

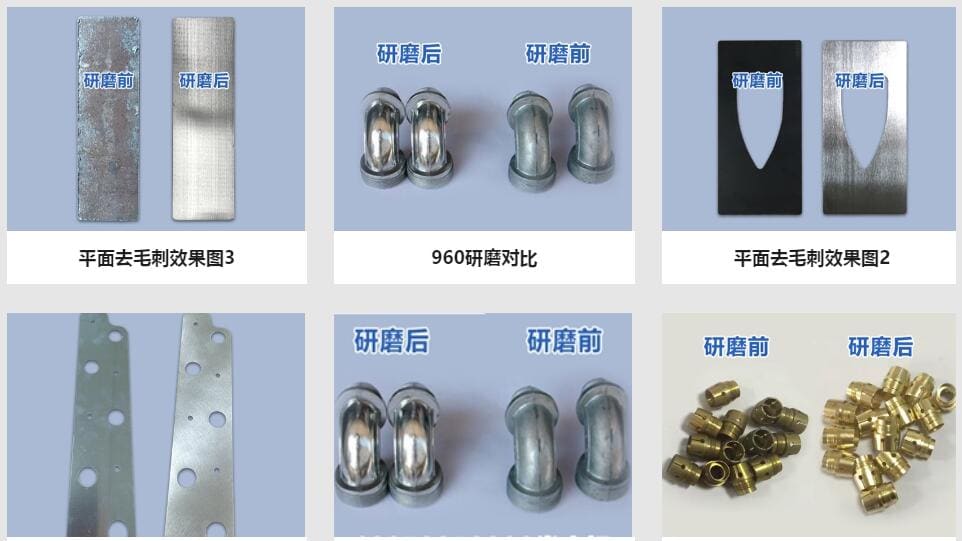

Samples after treated by Magnetic universal chamfer deburring machine

Samples after treated by Magnetic universal chamfer deburring machine