Description

Main Specifications of Bearing cylindrical tapered roller cold forging machine

| SPECIFICATION/MODEL | UNIT | ABF-62SL | |

| CUT-OFF DIA.MAX. | mm | 8 | |

| CUT-OUT LENGTH MAX. | mm | 95 | |

| KICK-OUT LENGTH MAX. | mm | 85 | |

| PKO | Mm | 15 | |

| CUT-OFF QUILL(D×L) | mm | ⊙28×46L | |

| MAIN DIE HOLE (D×L) | mm | ⊙50×100L | |

| PUNCH HOLE (D×L) | mm | ⊙40×90L | |

| RAM STROKE | mm | 150 | |

| FORGING POWER | Ton | 25 | |

| SIZE | M6 | ||

| PRODUCTS | MAX.LENGTH | mm | 80 |

| MAX.OUTPUT | pcs/min | 160 | |

| MAIN MOTOR | KW | 7.5 | |

| APPROX.WT. | KG | 6000 | |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

4.Configuration introduction:

- A set of standard feeding mechanism;

- A set of standard cutting mechanism;

- A set of standard clamp mechanism;

- A set of standard lubrication system;

- A set of standard fully enclosed safety enclosures;

- A set of standard pay-off reels;

- A set of special hand tools;

- A set of standard frequency conversion electrical cabinet, including fault detection function.

Application Scope of Bearing cylindrical tapered roller cold forging machine

High Speed Two Die Two Blows Cold Heading Machine is one kind of specialized machine with high efficiency and automation among forging machinery. High Speed Screws Cold Heading Machine are used for producing different kinds of self tapping screws,rivets,hinge pin and special parts in the field of fastener industry. Because of the advantage of the cold forging equipment itself and the superiority of cold forging technique, the High Speed Two Die Two Blows Cold Heading Machine also are widely used in different national economic fields for producing fasteners and non-standard parts for industry of building,aviation steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc.

Items can be produced by the Bearing cylindrical tapered roller cold forging machine

self tapping screws,rivets,hinge pin and special parts,chipboard screw,particle board screw,double ended screw,dowel screw,hanger bolt,drywall screw,lag screw,mirror screw,sheet metal screw,Twinfast screw,wood screw,Security head screw,self-drilling screw,self-tapping machine screw,Teks screw,auto fasteners,etc.

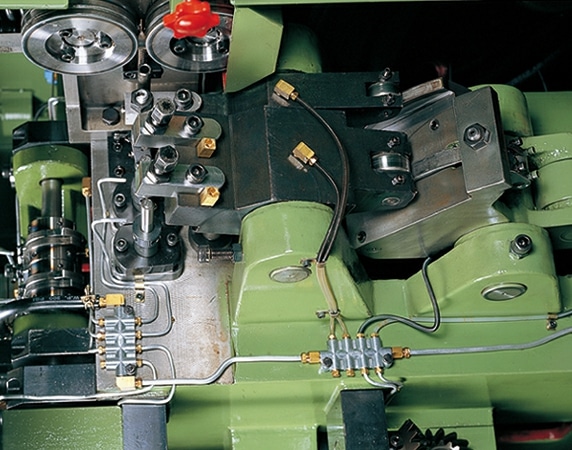

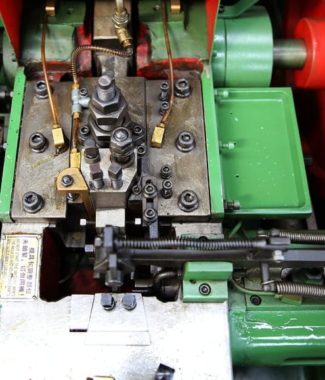

Salient Features of Bearing cylindrical tapered roller cold forging machine

1. Using high quality QT500-7 casting material , assure the cold heading machinemore compact structure and more stable performance.

2. The slipway adopts the high quality alloy and Copper alloy with special treatment which has a good wear-resisting property and long life of parts.

3. Main motor is equipped with speed-adjust transducer, PLC control system, computer automatic man-machine interface system(Optional), these equipment make lots of convenience for customer to adjust the dimension of the non-standard products.

4. The cold heading machine parts are machined by advanced CNC processing technology which ensure the precision of the requirement.

5. Perfect inspection system: short material inspecting and eliminating, inspection of the low location of oil pressure and air pressure, transfer system floating inspection system, overload, and lightload stop system to protect the lathe and dies and prolong the service life of them.

6. It is reasonable and best design for the layout of forced lubrication, oil pipe way and oil groove. Adequate and resonalbe lubrication system improves the equipment life and working performance.

7. High strengthened-material lathe bed, lengthened main and subsidiary slider structure and “pedrailtype” slider which is adopted domestically for the first time realize “zero space” assembling which assures the precision of the main slider movement and lengthens their service life of dies.

8. The main parts of all type machines have adopted strict casting procedure and annealing disposal to assure its steel hardness and precision.

9. The cold heading machine adopts famous brand-name products of the motor, bearing, pump etc. to improve the reliability of the machine.

10. Auto checker system is available and optional.

11. P.K.O synchronized knock out system makes the choice of molding technics flexible.

12.Touch screen and man-machine dialogue numerical control system are optional for meeting customer’s requirement, they are used for setting the length of thread pipe of rear knock out, the length of barrier and the feeding length, it is convenient for quick die change. This system has a memory capacity of 99 mnemonic modules for meeting the requirement of quick die change.

Main Standard and optional items for Bearing cylindrical tapered roller cold forging machine

|

|

| Auto checker for heading machine | PKO for heading machine |

|

|

| Screw conveyor for heading machine | Coil stand for heading machine |

Standard accessories of Bearing cylindrical tapered roller cold forging machine

1. One set of trial tools

2. One set of standard hand tools.

3. One set of standard spare parts.

4. One set of control Panel

5. One set of AC motor

6. Inside Lamp