Description

Salient Features of The Belt hook buckle wire banding welding machine

- Full automatic design with high efficiency.

- Easy to operate and adjustment.

- Advanced PLC control system optional.

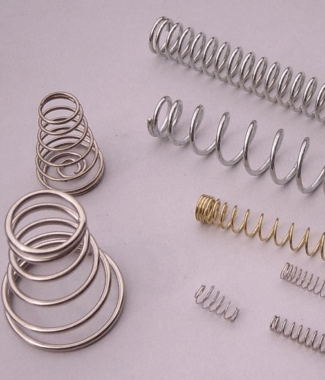

Scope of application: It is suitable for all kinds of miniature, small and medium-sized buckle products with a wire diameter of 1.0-5.0φ(mm). Various metal wires (circles, semicircles, ovals, squares, flats, sheets) such as iron wires, steel wires, copper wires, stainless steel wires, and aluminum wires are manufactured into different shapes. Such as D-shaped buckle, triangle buckle, square buckle, S hook, mountaineering hook, fish ear hook, 9-button, 8 button and other products.

The biggest features: ※ The stepper motor feeding is added, and the microcomputer control makes the feeding more precise.

※ Feeding the steamed bread to avoid the phenomenon that the thread is scratched.

※ Suitable for products with high surface finish and precise wire length

※ Automatic feeding, cutting, forming, pushing, and uninterrupted production.

※ Easy to operate, stable quality, fast delivery and high production efficiency.

※ Four-speed shifting, easy to operate, easy to switch. According to the material, line length, length and shape of the workpiece to be processed

Same and choose the appropriate speed.

※ Easy to adjust, only need to change the mold to produce different products. Excellent materials, excellent workmanship, high comprehensive performance and long service life

Long.

Parameters of The Belt hook buckle wire banding welding machine

The original wire diameter: 1.0-5.0 (mm) ф

Feeding length: 400 (mm)

Mechanical power: 2.2KW 380V 1400rpm

Mechanical speed regulation: four-stage variable speed gearbox (with small hydraulic system)

Production speed: 30-60-80-120 (times / minute)

Mechanical weight: 700kg

Mechanical size: 1800*700*1500 (length * width * height)