Description

Application Scope of Five Stroke Bolt Parts Making Machine

Five Stroke Bolt Making Machine is one kind of specialized machine with high efficiency and automation among forging machinery. Cold forging technique and automatic cold forging machines are used for producing different kinds of bolts, screws, rivets,special parts and nuts in the field of fastener industry. Because of the advantage of the cold forging equipment itself and the superiority of cold forging technique, the Five Stroke Bolt Making Machine also are widely used in different national economic fields for producing fasteners and non-standard parts for industry of aviation steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc.

Items can be produced by the Five Stroke Bolt Parts Making Machine

Flange Bolts, Socket bolts,Hex Bolts, Fastener and Bolts, Hex Cap Screws, Spring Center bolts, Hex Socket Cap Screws, Carriage bolts, solid rivets, square head set screws, truss head track bolts, U Bolts, Fin Neck Bolts, shoulder bolts, coil thread bolts, Structure Liner Bolts, extra long Bolts, Hub Bolts fetter drive screws, wheel bolts, t-head bolts, Flange Bolts, eye bolts, shackle bolts, track bolts, wheel bolts, hex cap screws,auto fasteners,etc.

Specifications of Five Stroke Bolt Parts Making Machine

| Model | Unit | APF-65S | APF-85S | APF-105S | APF-135S | APF-135L | APF-165S |

| Max. Material Cutting Diameter | Mm | 8 | 11 | 13 | 16 | 16 | 18 |

| Max. Material Cutting Length | Mm | 100 | 110 | 140 | 140 | 190 | 190 |

| K.O Length/P.K.O Length | Mm | 80/20 | 90/26 | 115/30 | 115/30 | 165/30 | 170/40 |

| Cutting Die Size | Mm | 30*45 | 35*50 | 45*59 | 63*69 | 63*69 | 75*100 |

| Main Die Size | Mm | 50*110 | 60*120 | 75*135 | 86*190 | 86*190 | 108*200 |

| Punch Die Size | Mm | 40*90 | 45*115 | 53*115 | 60*130 | 60*130 | 75*185 |

| Product Length | Mm | 10-70 | 15-75 | 15-110 | 20-110 | 20-160 | 20-160 |

| Max. Production Speed | Pcs/Min. | 200 | 160 | 140 | 115 | 100 | 90 |

| Main Motor Power | Kw | 15 | 22 | 30 | 37 | 37 | 55 |

| Appro. Machine Weight | Ton | 11 | 16 | 20 | 30.5 | 31 | 52 |

| Model | Unit | APF-205S | APF-205L | APF-255S | APF-255L | APF-305S |

| Max. Material Cutting Diameter | Mm | 23 | 23 | 32 | 32 | 36 |

| Max. Material Cutting Length | Mm | 240 | 360 | 380 | 450 | 420 |

| K.O Length/P.K.O Length | Mm | 220/50 | 325/50 | 320/50 | 410/60 | 380/60 |

| Cutting Die Size | Mm | 75*120 | 75*120 | 99*150 | 99*150 | 118*180 |

| Main Die Size | Mm | 125*240 | 125*345 | 148*355 | 148*450 | 168*420 |

| Punch Die Size | Mm | 90*215 | 90*215 | 120*270 | 120*270 | 140*300 |

| Product Length | Mm | 25-210 | 100-305 | 60-310 | 120-390 | 70-370 |

| Max. Production Speed | Pcs/Min. | 70 | 65 | 60 | 60 | 50 |

| Main Motor Power | Kw | 75 | 75 | 110 | 110 | 132 |

| Appro. Machine Weight | Ton | 75 | 95 | 140 | 150 | 200 |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

Salient Features of Five Stroke Bolt Parts Making Machine

1. The air clutch brake system has been designed to actuate with low current and as “inching”, “single stroke” and “continuous running”. Except “inching”, the machine will always stop at the backward position of the main slider while operating in largest space.

2. Two sorts of transfers system for customer to choose: swing type (general equipped) and universal type (optional), equipped with pneumatic gripper, it can simplify the demand of operation, and is more stable when the machine runs at high speed.

3. Main motor is equipped with speed-adjust transducer, PLC control system, computer automatic man-machine interface system(Optional), these equipment make lots of convenience for customer to adjust the dimension of the non-standard products.

4. Feeding wheel and claw system are both drived by cylinder, the claw can stretch automatically when it goes back in order to reduce abrasion and noise. Feeding material and stop feeding material are controlled by two claws, the feeding material system is equipped with device for avoiding material draw back.

5. Perfect inspection system: short material inspecting and eliminating, inspection of the low location of oil pressure and air pressure, transfer system floating inspection system, overload, and lightload stop system to protect the lathe and dies and prolong the service life of them.

6. When the customer prepare to adjust the side cutting screw, they only need to adjust side cam’s station position, then they can achieve side cutting purpose. When the workpieces need not side cutting, customer can reset it to achieve the change from side cutting to former station.

7. High strengthened-material lathe bed, lengthened main and subsidiary slider structure and “pedrailtype” slider which is adopted domestically for the first time realize “zero space” assembling which assures the precision of the main slider movement and lengthens their service life of dies.

8. The main parts of all type machines have adopted strict casting procedure and annealing disposal to assure its steel hardness and precision.

9. Circle cutting die station assures the sheared material shouter than billet diameter which also can achieve accurate right angle cutting.

10. Auto sizing material stopper can adjust the precision of material size in the state of machine running.

11. P.K.O synchronized knock out system makes the choice of molding technics flexible.

12. Transfer finger moving and cutting cams are calculated via professional computer software to make machine stable in state of high speed forging.

13.There is imported converter available in electrical system, so it is easy to run the former with stepless variable drive PLC also is used for automatically inspecting the working mode of the former with the functions of fault alarm and fault display.

14.Touch screen and man-machine dialogue numerical control system are optional for meeting customer’s requirement, they are used for setting the length of thread pipe of rear knock out, the length of barrier and the feeding length, it is convenient for quick die change. This system has a memory capacity of 99 mnemonic modules for meeting the requirement of quick die change.

Main Structure And Parts Introduction

|

|

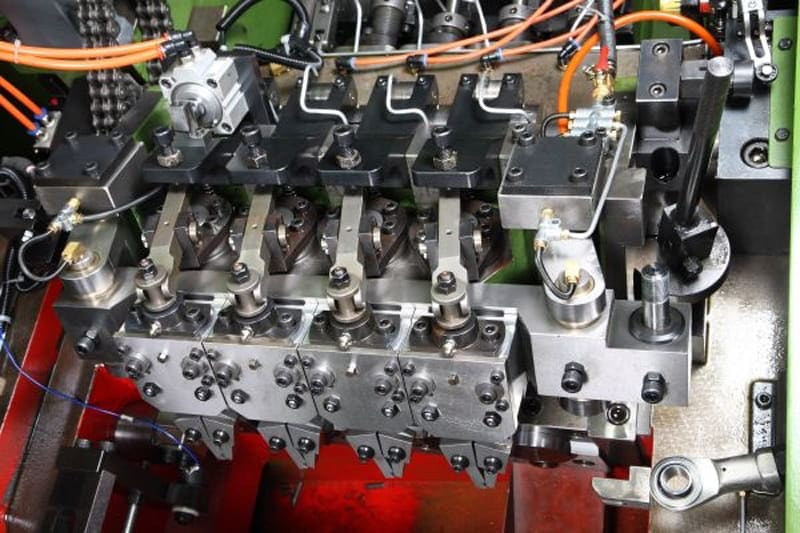

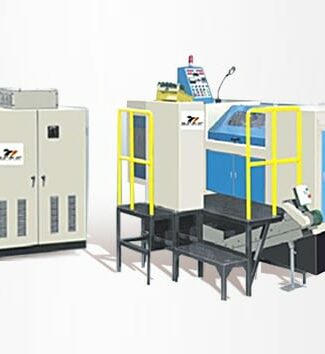

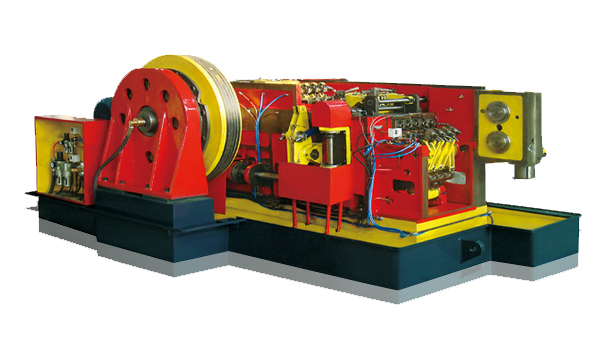

| Bolt maker body without enclosure | High precision main slider |

|

|

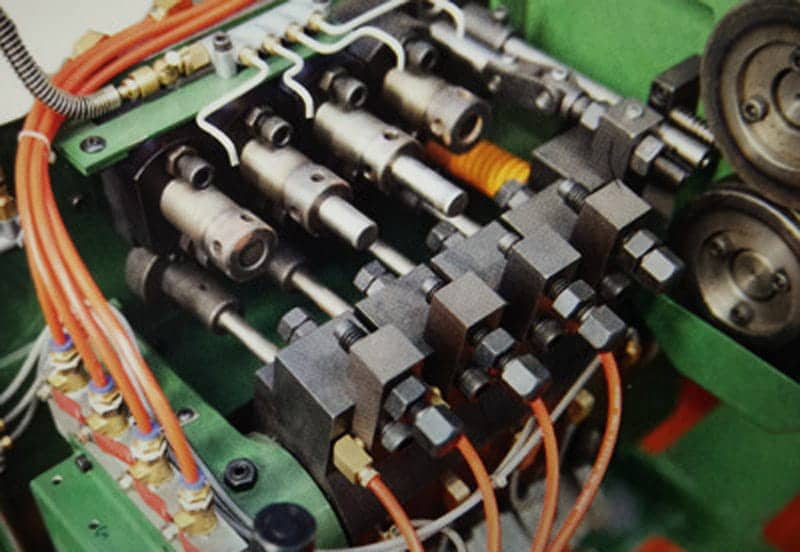

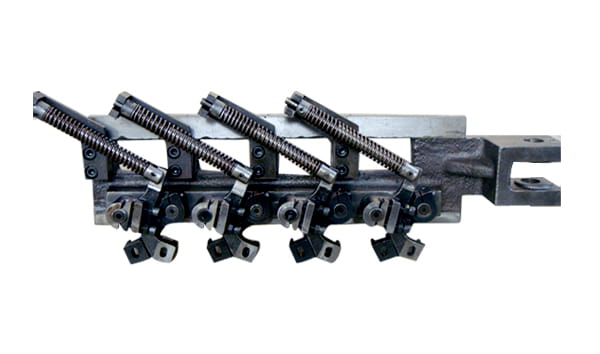

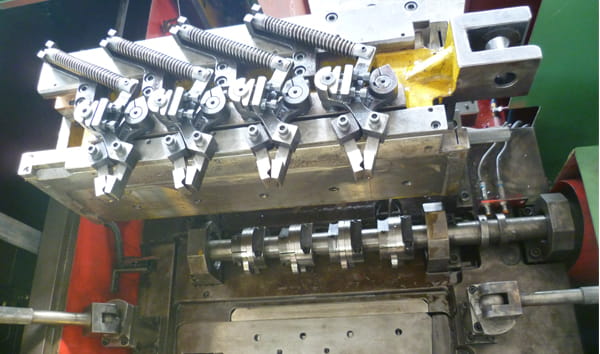

| Spring clamps system | Transfer fingers system |

|

|

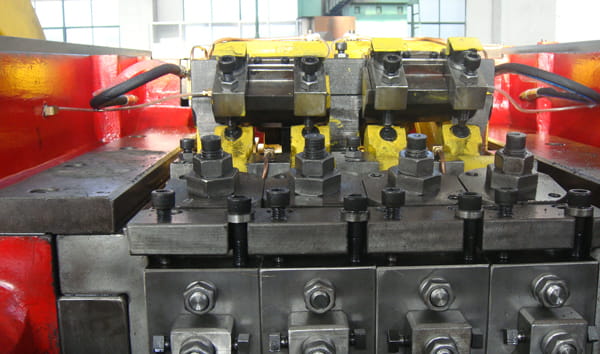

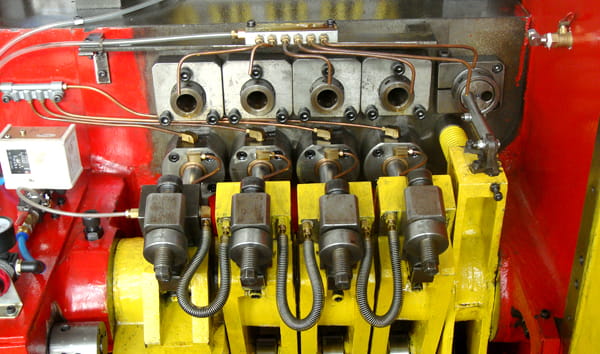

| PKO system | Wire material cutting system |

|

|

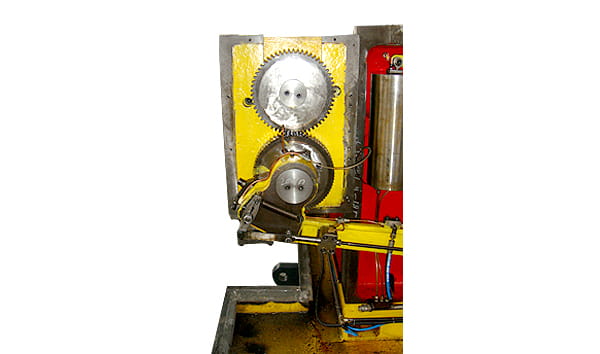

| Clutch system with brake device | Gears transmission system |

|

|

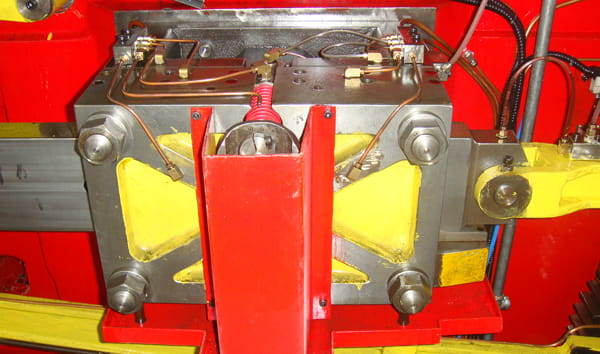

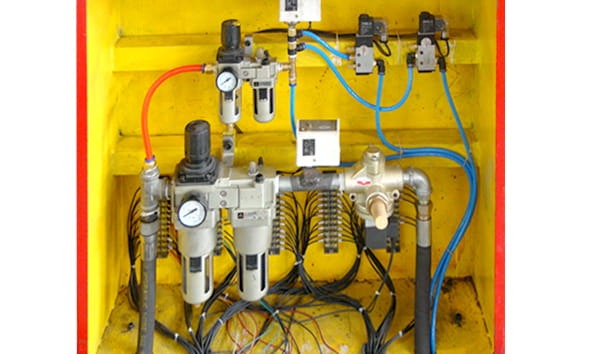

| Hydraulic and pnumatic control system | Material discharge mechanism with convex plate quick replace function |

|

|

| Wire material feeding system | Spiral bevel tranmission driving system |