Description

Running video of Full Automatic Special Shape Nut And Parts Thread Tapping Machine

Salient Features of Full Automatic Special Shape Nut And Parts Thread Tapping Machine

- Full automatic design with high speed and efficiency.

- Easy to operate and adjustment.

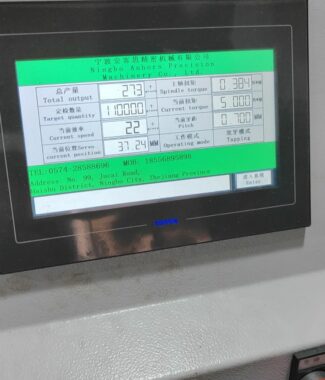

- Advanced PLC control system optional.

Application Scope of Full Automatic Special Shape Nut And Parts Thread Tapping Machine

Full Automatic Nut Tapping Machine is one kind of specialized machine with high efficiency and automation among forging machinery. Full Automatic Nut Tapping Machine are used for producing different kinds of nuts and nut shape parts in the field of fastener industry. Because of the advantage of the cold forging equipment itself and the superiority of cold forging technique, the Full Automatic Nut Tapping Machine also are widely used in different national economic fields for producing fasteners and non-standard parts for industry of building,aviation steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc.

Items can be produced by the Full Automatic Special Shape Nut And Parts Thread Tapping Machine

Hex nut,hex flange nut,round nut,square nut,Cap Nuts,Castle Nuts,Coupling Nuts,Flange Serrated Nuts,Hex Machine Nuts,Keps-K Lock Nuts,Knurled Thumb Nuts,Nylon Hex Jam Nuts,Nylon Insert Lock Nuts,Prevailing Torque Lock Nuts,T-Nuts,Tri-Groove Nuts,Wing Nuts,drop in anchors,Acorn nut,cap nut,Barrel nut,Cage nut,Sleeve nut,Split nut,Swage nut,Weld nut,.

Main Specifications:

| Model | Rotary (PER MIN.) | Air Pressure(KG) | Main Motor(KW) | Lub. Motor(KW) | Dimension(CM) | Weight(T) |

| ATS-M3 | 1400 | 2-3 | 0.55*2 | 0.25 | 180*130*150 | 1 |

| ATS-M4 | 1340 | 4-5 | 0.55*2 | 0.25 | 180*130*150 | 1 |

| ATS-M5 | 1300 | 4-5 | 0.55*2 | 0.25 | 180*130*150 | 1 |

| ATS-M6 | 940 | 4-5 | 0.55*2 | 0.25 | 180*130*150 | 1 |

| ATS-M8 | 740 | 5-6 | 0.75*2 | 0.25 | 180*130*150 | 1 |

| ATS-M10 | 650 | 6-8 | 1.1*2 | 0.25 | 180*130*150 | 1 |

| ATS-M12 | 560 | 6-8 | 1.1*2 | 0.25 | 180*130*150 | 1 |

| ATS-M14-M33 | 420-170 | 6-8 | 1.5*2 | 0.25 | 180*150*200 | 1.5 |