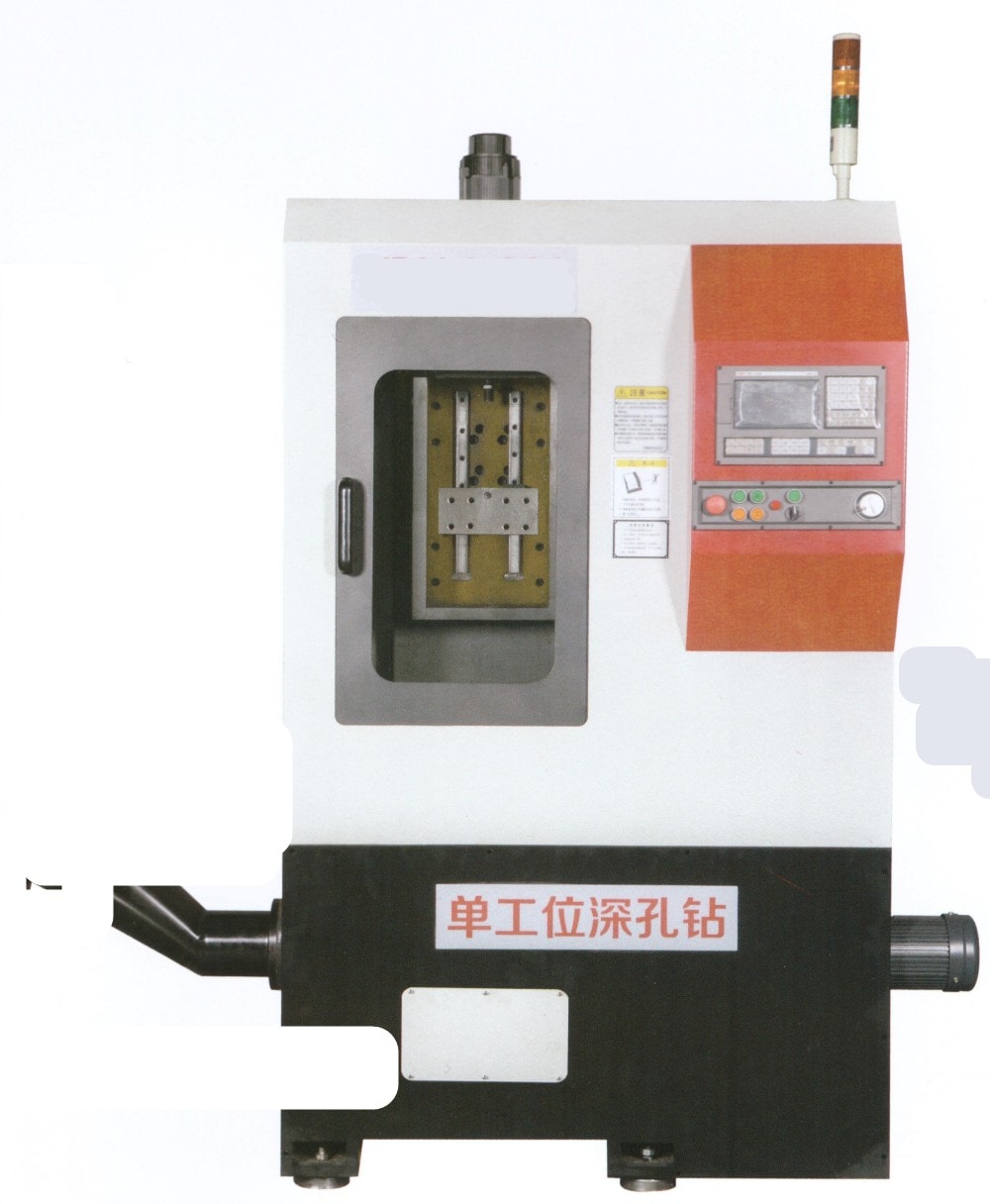

Description

Specifications of High efficiency single station deep hole drilling machine

Number of spindles:1

Drilling diameter range: 4 – 20mm (30mm optional)

Maximum drilling depth:300Mm

Maximum length of workpiece:300Mm

Drilling coaxiality:<=0.3/300

Drilling aperture accuracy:IT7-IT10

Drilling roughness:Ra0.8-Ra6.3

Maximum spindle speed:5000Rpm

Feed rate:0-300Mm/min

fast shift speed:0-3000Mm/min

Spindle motor total power:5.5 (7.5 optional)Kw

Total power pump motor:5.5Kw

Feed servo motor power:2.3Kw

Maximum coolant flow:50L/min

Maximum coolant pressure:100Bar

Machine dimensions:2000x2300x2000Mm

Total machine weight:2.5t

Control method:PLC or CNC

Application scope of High efficiency single station deep hole drilling machine

Scope of application: Mainly used for batch and efficient processing of deep holes and precision small diameter holes boring.

Features of High efficiency single station deep hole drilling machine

Servo drive regulation number of rotary.

Precision high-speed spindles regulate the speed through servo drives,for different materials and different apertures

Machining, the corresponding speed can be set as needed, and the optimum cutting line speed can be easily obtained.

Low processing energy consumption in batch processing

Hydraulically controlled workpiece clamping action

The workpiece clamping action is realized by hydraulic pressure, and the workpiece fixing is convenient, quick and easy to operate.

The work consistency is high, the stability is good, and the quality of the workpiece is easy to guarantee.

Operating system

This machine is a microcomputer controlled machine tool, the system can display fault information, processing count,

Timing, storage procedures, detection of the total length of the workpiece, error-proof clamping, empty clamping, etc.

Shorter tool length and significantly improved efficiency

The inverted structure is used and remove the traditional structure of chip discharge box, which is greatly shortened the length of the tool increases the rigidity of the tool and increases the machining efficiency.

Vertical structure and smoother chips discharge

Subverting the horizontal structure of the traditional deep hole drill, the tool is below, the workpiece is on the top, and the chip removal is more smooth, significantly improved the efficacy.