Description

Application Scope of Seven Stroke Nut Part Former

Multi Stroke Nut Part Former is one kind of specialized machine with high efficiency and automation among forging machinery. High Speed Cold Nut Former are used for producing different kinds of self tapping screws,rivets,hinge pin and special parts in the field of fastener industry. Because of the advantage of the cold forging equipment itself and the superiority of cold forging technique, the Multi Stroke Nut Part Former also are widely used in different national economic fields for producing fasteners and non-standard parts for industry of building,aviation steamer, machinery, rail traffic, vehicle, motorcycle, bicycle, sewing machine, construction, furniture, light industry and daily necessities, etc.

Items can be produced by the Seven Stroke Nut Part Former

Hex nut,hex flange nut,round nut,square nut,Cap Nuts,Castle Nuts,Coupling Nuts,Flange Serrated Nuts,Hex Machine Nuts,Keps-K Lock Nuts,Knurled Thumb Nuts,Nylon Hex Jam Nuts,Nylon Insert Lock Nuts,Prevailing Torque Lock Nuts,T-Nuts,Tri-Groove Nuts,Wing Nuts,drop in anchors,Acorn nut,cap nut,Barrel nut,Cage nut,Sleeve nut,Split nut,Swage nut,Weld nut,.

Specifications of Long Stroke Seven Station Nut Part Former

| Model | Unit | APF11B-7SL | APF14B-7SL | APF14B-7SL | APF17B-7SL | APF17B-7SL | APF19B-7SL |

| Max. Cut Off Diameter | MM | 11 | 14 | 15 | 17 | 17 | 19 |

| Max. Forging Length | MM | 35 | 50 | 70 | 50 | 70 | 50 |

| Kick Out Length | MM | 45 | 60 | 90 | 60 | 90 | 65 |

| Main Slider Stroke | MM | 130 | 160 | 220 | 160 | 220 | 170 |

| Die Pitch | MM | 50 | 60 | 60 | 70 | 70 | 80 |

| Forging Force | TON | 60 | 130 | 140 | 150 | 160 | 190 |

| Max. Output Speed | Pcs/Min. | 110 | 80 | 75 | 75 | 75 | 70 |

| Main Motor | KW | 15 | 22 | 30 | 30 | 37 | 37 |

| Appro.Weight | TON | 4.8 | 9 | 9 | 11 | 11 | 17 |

| Appro. Dimension | CM | 250*170*130 | 350*210*150 | 350*210*150 | 370*230*160 | 370*230*170 | 450*240*190 |

| Model | Unit | APF19B-7SL | APF22B-7SL | APF22B-7SL | APF24B-7SL | APF24B-7SL | APF33B-7SL |

| Max. Cut Off Diameter | MM | 19 | 22 | 22 | 22 | 24 | 32 |

| Max. Forging Length | MM | 80 | 50 | 80 | 50 | 70 | 70 |

| Kick Out Length | MM | 90 | 60 | 90 | 60 | 90 | 90 |

| Main Slider Stroke | MM | 220 | 160 | 220 | 160 | 220 | 280 |

| Die Pitch | MM | 80 | 80 | 80 | 100 | 100 | 140 |

| Forging Force | TON | 200 | 220 | 250 | 280 | 300 | 400 |

| Max. Output Speed | Pcs/Min. | 70 | 70 | 70 | 70 | 65 | 60 |

| Main Motor | KW | 45 | 45 | 45 | 55 | 55 | 150 |

| Appro.Weight | TON | 18 | 20 | 21 | 30 | 30 | 60 |

| Appro. Dimension | CM | 450*240*190 | 450*240*190 | 450*240*190 | 550*300*220 | 550*300*220 | 700*350*250 |

1.We reserves the right to modify the above parameters, and may not be notified if there is any modification;

2.The most suitable production speed of the product depends on the shape, size and material of the product;

3.The maximum material shear diameter and the suitable product diameter listed in the table are calculated as medium carbon alloy steel, equivalent to 10.9 high strength screws.

Salient Features of Seven Stroke Nut Part Former

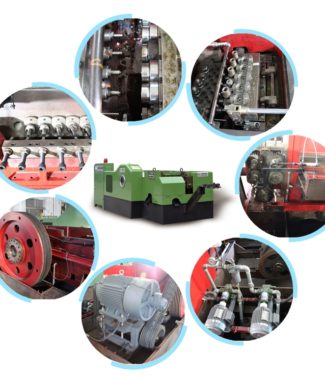

1.The crankshaft and the body are connected by the best SKF bearings or high wear-resistant alloy copper tiles. The load bearing capacity is large, the service life is long, the maintenance cost is low, the friction resistance is small, the operation is fast and flexible, and much power saving.

2.The body is made of ductile iron with added alloy, which has high tensile strength and good anti wear resistance.

3.Adopting two-stage gear transmission system, the transmission efficiency is high and the transmission torque is large.

4.Equipped with pneumatic clutch brake to reduce motor power consumption and easy to operate the machine with inching movement function.

5.The cutting system uses the guide plate driving cutter desing,the guide plate reciprocates movement, the cutting force is transmitted linearly, the force is large and steady,the dynamic balance is good.

6.The transfer finger system can be flipped or translated by 180 degrees. Conducive to the molding process arrangement.

7.Equipped with variable frequency speed control device, can be stepless speed regulation within a certain range.

8.Equipped with fault detector and safety protection device, it will automatically stop when the equipment fails, and it will protect the equipment and forging die.

9.The feeding box is equipped with a back stop device to improve the feeding accuracy.

10.The main slide of the six-station and seven-station machine adopts the T-type design, the slider operation is more stable, and one more forming station than the five-station, which is more conducive to the processing of products with higher precision and more complicated shapes.

11.The main slider side plates adopts an adjustable design to ensure the running accuracy under long-term use.

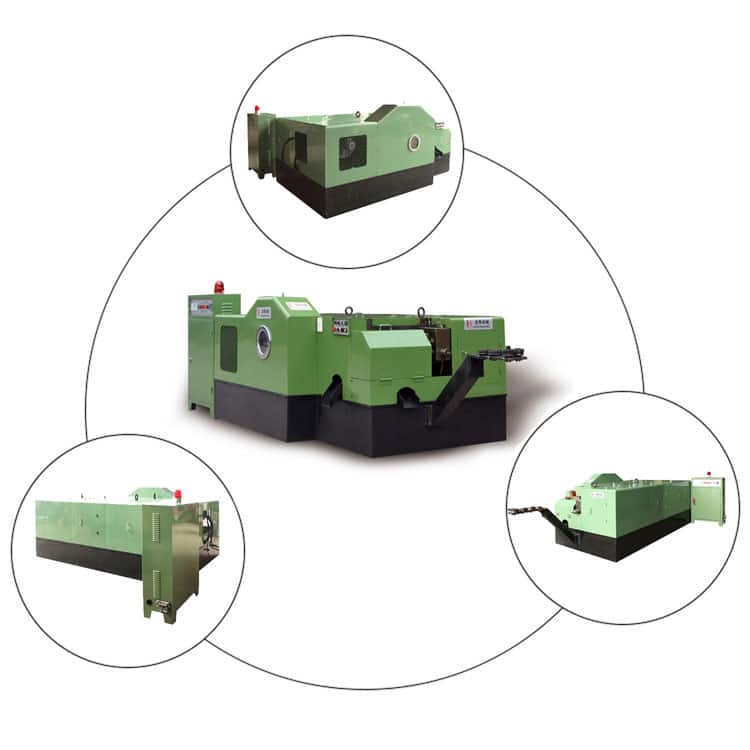

Main Structure and Designs of Seven Stroke Nut Part Former