Description

Features of AMY-S laser precision welding machine for jewelry

The laser welding machine can effectively handle the welding and repairing of all minor parts with the fusion technology of laser high thermal energy and centralized fixed point, making up the deficiency of traditional argon arc welding technology in repairing the fine surface of welding, avoiding the two thresholds of thermal strain and post-treatment, and greatly saving the production cycle of jewelry. The main advantages are tailor-made for the jewelry industry, with unique institutional design, suitable for the repair of various large, medium and small jewelry.

1. Adopt imported ceramic concentrated cavity, resistant to corrosion and high temperature, with cavity life of 8-10 years and xenon lamp life of more than 8 million times.

2. Adopt advanced automatic shading technology to eliminate eye irritation at work.

3. The laser head can rotate 360 degrees, and the whole part can rotate 360 degrees. It can move from front to back, from top to bottom, from left to right.

4. The working table can be moved up and down by electric motor and move in three dimensions.

5. The photoelectric size can be adjusted electrically.

Specifications of AMY-S laser precision welding machine for jewelry

| Laser power | 50W-200W |

| Table triaxial stroke | 130mm*95mm*150mm |

| Table three-axis dimensions | 450mm*350mm |

| Total weight | 300kg |

| Machine power supply | 380V/±10%/50hz/60A |

| Laser type | Nd:YAG pulse |

| Spot adjustment range | 0.1-3.0mm |

| Light spot size | 0.2-3.0mm |

| Optical maser wavelength | 1064nm |

| Depth of weld | ≤2mm |

| Pulse width | 0.1-25ms |

| Pulse frequency | ≤50Hz |

| Laser output focal length | 80mm/100mm/120mm/200mm |

| Laser cooling | Water cooled |

| Observe the positioning | Microscope |

| Control system | PC or PLC |

| Shielding gas | 1 Road |

| Equipment size | 1600mm*800mm*1500mm |

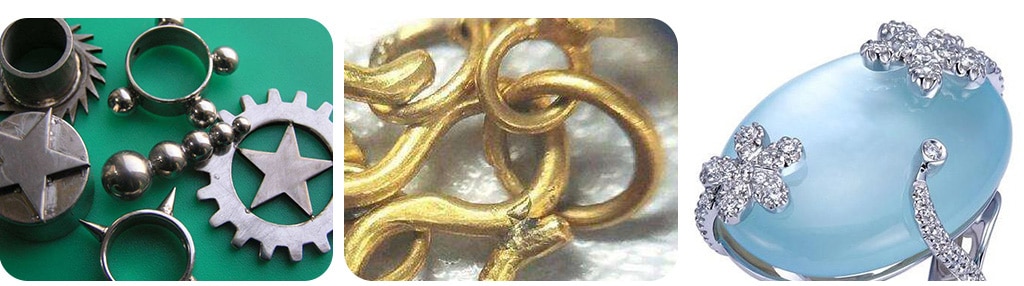

Welded Samples of AMY-S laser precision welding machine for jewelry

Samples of AMY-S laser precision welding machine for jewelry