Description

Running video of ATC-400 High Speed Self Tapping Screws Tail End Point Cutting Machine

Application of ATC-400 High Speed Self Tapping Screws Tail End Point Cutting Machine

The Automatic Self Drilling Screws Tail End Point Cutting Machine designed for cutting out the tail of stainless steel and mild steel self drilling screws,suitable for extra long self-drilling screw upto 400mm.

1. The Self-Drilling Screws are popular fasteners which widely used in industries like building,car manufacture,etc.

2. The Self-Drilling Screws have features of drilling & fixing easily.

3. The material of Self-Drilling Screw is carbon steel wire AISI 1018-1022 or stainless steel material. Usually the product have five procession: (1) Cold heading by cold heading machine (2) Drilling point forming by Self-Drilling Screw Making Machine (3) Thread rolling by Thread rolling machine (4) Heat treatment by mesh belt furnace (5) Electroplating by zinc plating equipment.

4. The Self-Drilling Screw Making Machine is used to form the drilling point of the screw.

Features of ATC-400 High Speed Self Tapping Screws Tail End Point Cutting Machine

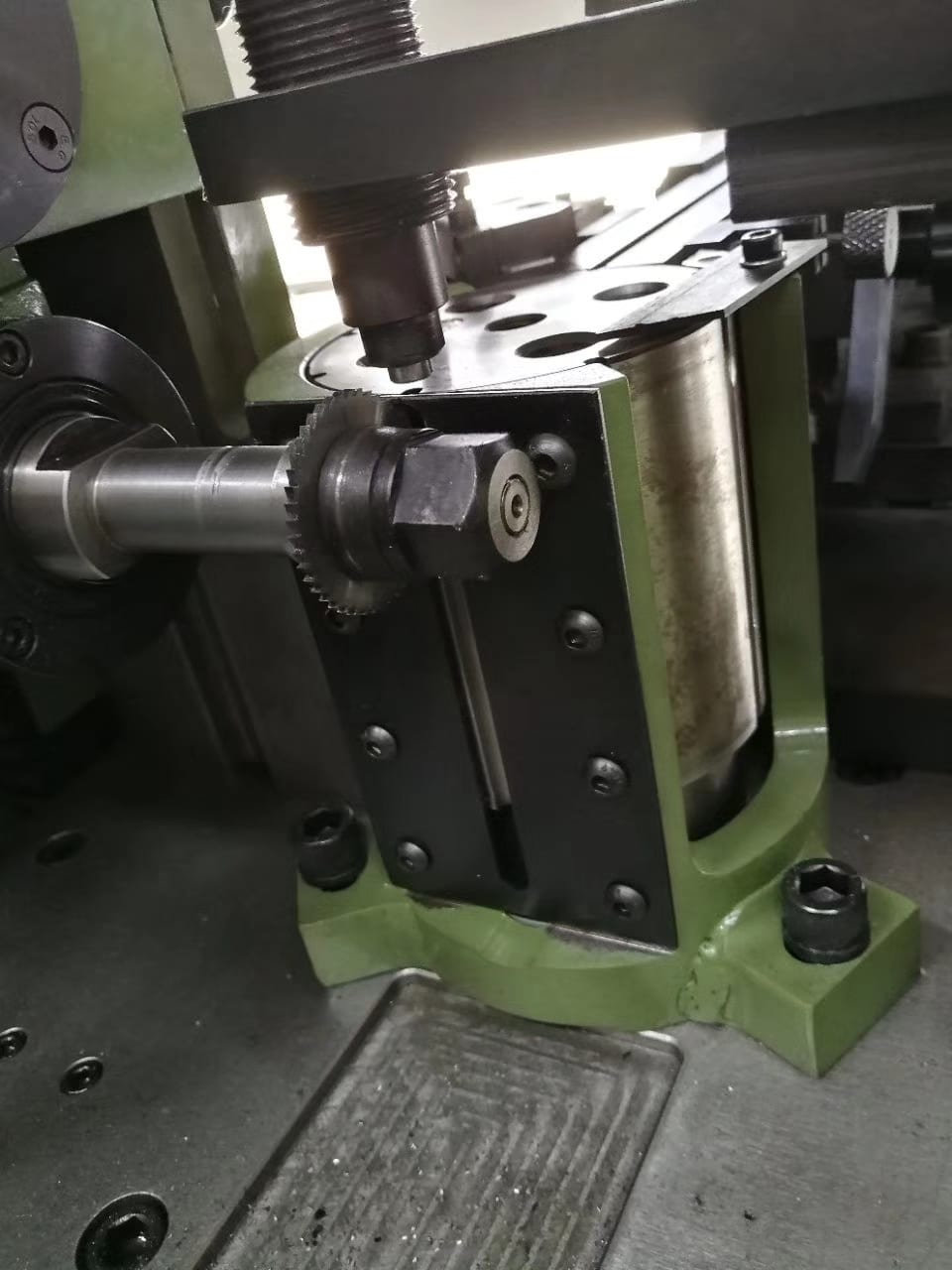

1. Working bench is designed by die set for easy and simple operation and maintenance.

2. Monitor and control by Program Logical Control(PLC) system, trouble and alarm displayed on the board by Light Emitted Display (LED) system, so the trouble can be easily noted and sorted.

3.Key parts like rotary and sliding parts have been processed under heat-treatment for good wear-resisting.

4.High speed and automatic, noiseless and energy-saving.

5.High precision, original accurate position return and absolute synchronizing.

Tail cutted carbon steel self drilling screw

Tail cutted stainless steel self drilling screw

Main Technical Parameters of ATC-400 High Speed Self Tapping Screws Tail End Point Cutting Machine

| Model | ATC-400 |

| Appro. Dimension | 220*150*170CM |

| Power | INVERTER 2.2KW,HIGH FREQUENCY INVERTER 1.5KW MOTOR 1.5KW,0.75KW |

| Screw diameter and length range | DIA:2.8-8MM(6#-18#),LENGTH 20-400MM |

| Speed | 10-300 PCS PER MIN |

| Control method | PLC AUTOMATIC CONTROL |

| Detection system | TOUCH SCREEN MAN-MACHINE FAULT DETECT AND DISPLAY |

| Transmission type | INDEX PLUS INVERTER |

| Screws separate type | INDEX HIGH SPEED PRECISION SEGMENTATION |

| Appro. Weight | 1.3TON |