Description

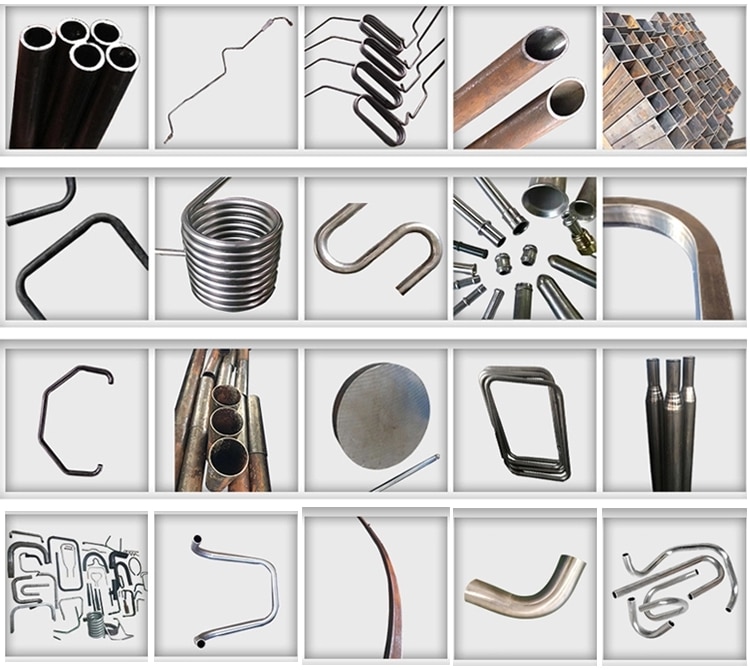

Application of pipe bending machine

Auto parts (brake tubing, bumper, muffler, seat).

Motorcycle manufacturing, bicycle industry, fitness equipment,

Air conditioning and refrigeration, steel furniture, sanitary equipment and other industries.

Adapted material:steel pipe, stainless steel tube, copper pipe, aluminum pipe,etc.

|

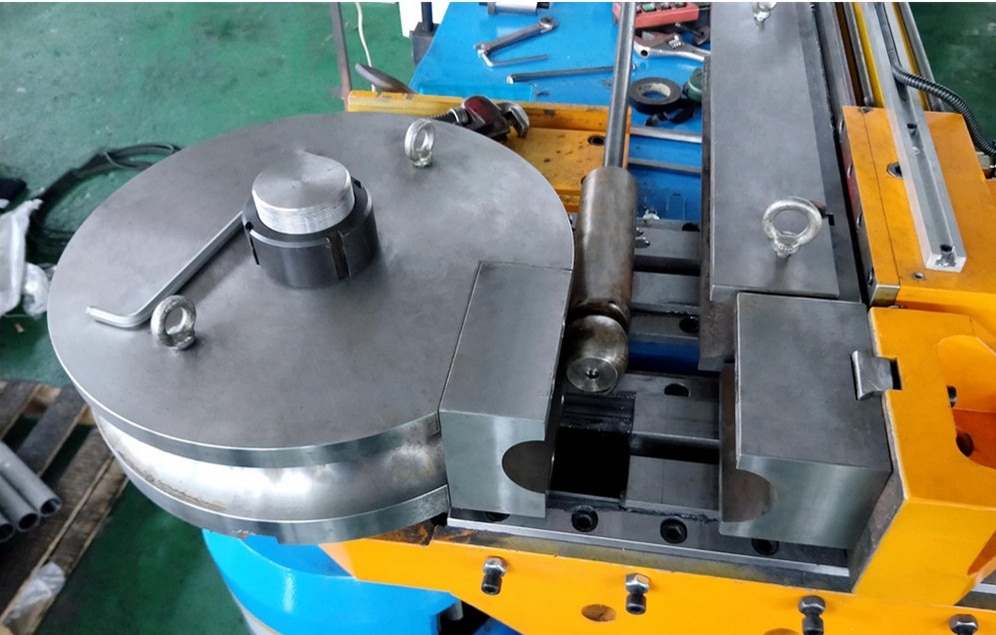

AW50CNC Steel Metal Tube Pipe Bending Machine structure 1

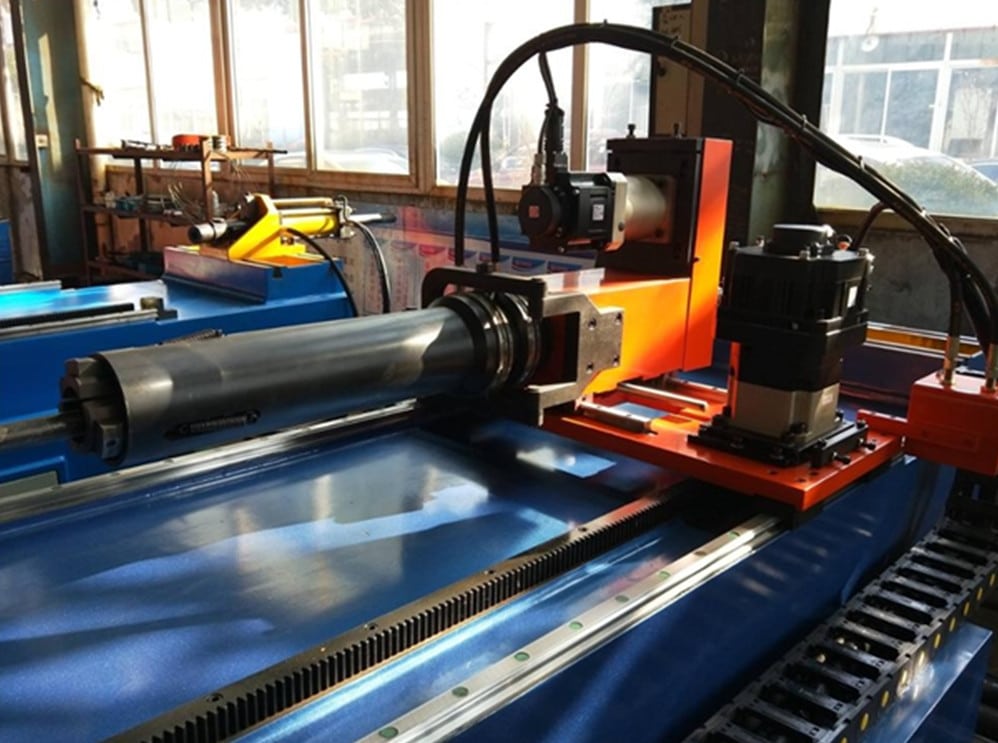

AW50CNC Steel Metal Tube Pipe Bending Machine structure 2

Features of pipe bending machine

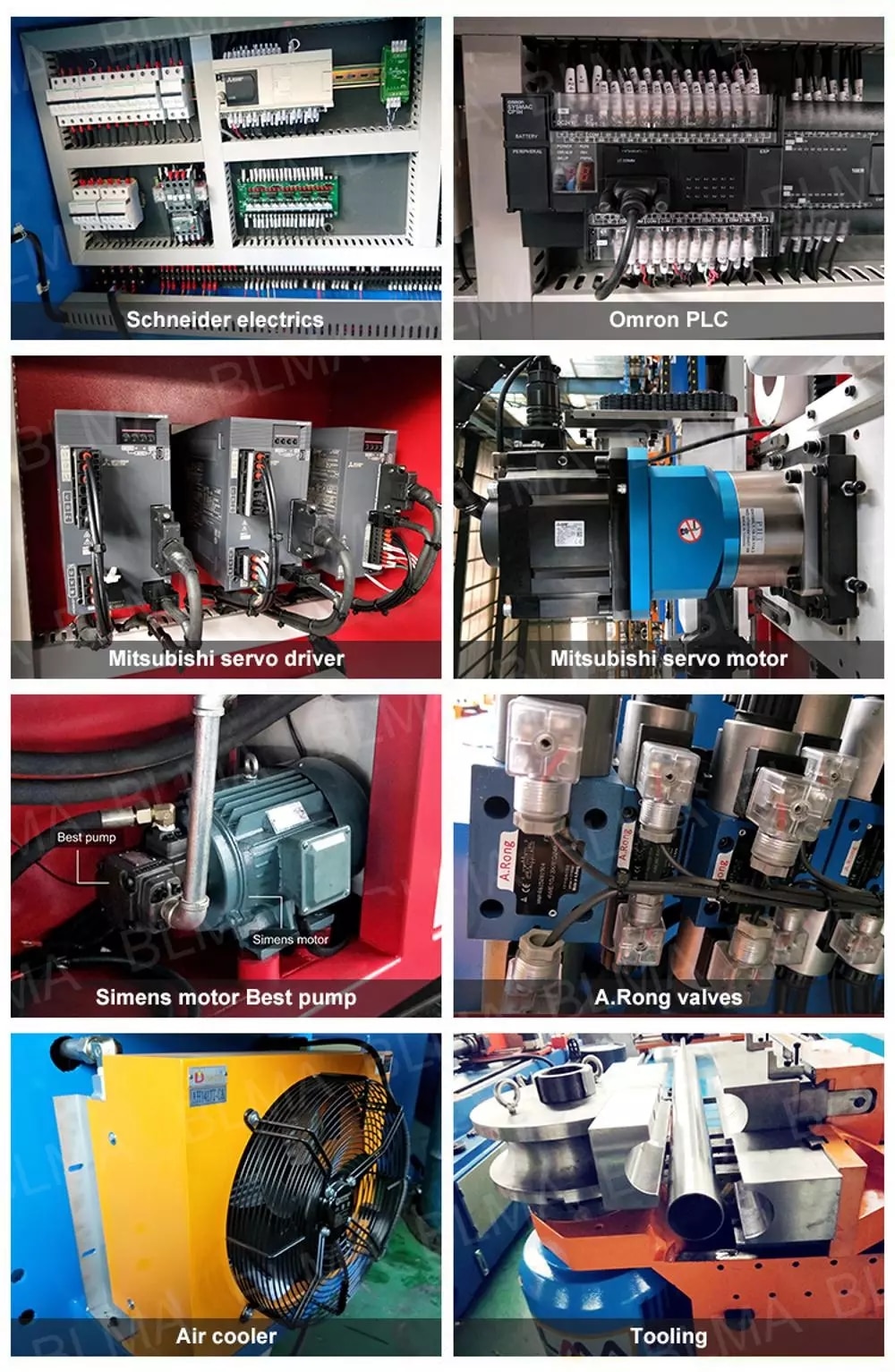

- Interactive PLC touch screen offers easy access to auto and manual operating modes.

- System diagnostics and multiple language capability.

- Standard clockwise bending direction.

- Fully hydraulic clamping on clamp die and pressure die.

- Drop-way hydraulic clamping.

- Direct acting hydraulic pressure die with adjustable speed valve.

- Maximum 100 sets of program storage,Maximum 32 bends for each program.

- With Independent programmable speeds Y, B, and C axes.

- Programmable material spring back settings for each bend angle.

- Automatic release of tube prior to final bend.

- Bending Axis-Driven by Cylinder,Feeding Axis-Driven by Servo Motor,Rotating Axis-Driven by Servo Motor.

- Obtain quality repeatable bends in steel, stainless, aluminum, titanium and brass.

- Foot Pedal Cycle start.

- With Air Cooling System.

- One set of Tooling for Draw Bending.

- Wiper die Bracket.

- 1 Mandrel Rod.

- Operation and Maintenance Manual.

- Tool Box with Adjusted Tools.

- Electric: As required (3 phase 220V or 380V or 415V…)

AW50CNC Steel Metal Tube Pipe Bending Machine parts brands

Optional items of pipe bending machine

- Industrial Computer Controlling

- Anticipate Mandrel Extraction

- Automatic mandrel/machine lubrication

- Anti-clockwise bending direction

- Machine effective length over mandrel

- Safety Mat