Description

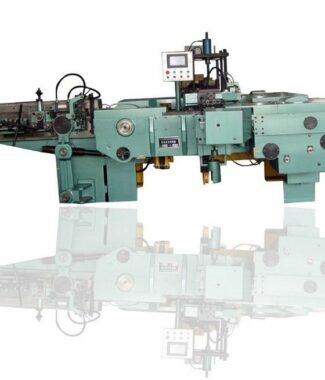

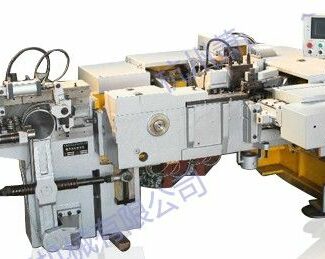

Salient Features of Buckle hydraulic wire bending machine with pipe part assembly

- Full automatic design with high efficiency.

- Easy to operate and adjustment.

- Advanced PLC control system optional.

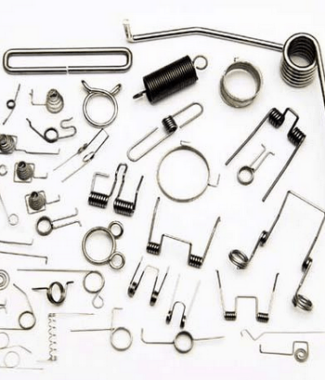

This machine is suitable for steel wire, iron wire, aluminum wire, copper wire, stainless steel wire to make different shapes, can be letters and numbers. For example: packing buckle, ear hook, D buckle, S buckle, 9-pin, five-pointed star, mountaineering hook, hook, triangle buckle, square buckle, bolt, word clip and other various types of products, just replace the mold can. It is used to manufacture wire products used in the hardware industry, toy industry, stationery industry, garment industry, lighting industry, jewelry industry, electronics industry and other electrical products and handicrafts. This machine feeds longer and is suitable for making some smaller Hardware. If used as a hanger hook, you can make a folding or round head product in one go.

The biggest features:

※ The stepper motor feeding is added, and the microcomputer control makes the feeding more precise.

※ Feeding the steamed bread to avoid the phenomenon that the thread is scratched.

※ Suitable for products with high surface finish and precise wire length

※ Automatic feeding, cutting, forming, pushing, and uninterrupted production.

※ Easy to operate, stable quality, fast delivery and high production efficiency.

※ Four-speed shifting, easy to operate, easy to switch. According to the material, line length, length and shape of the workpiece to be processed

Same and choose the appropriate speed.

※ Easy to adjust, only need to change the mold to produce different products. Excellent materials, excellent workmanship, high comprehensive performance and long service life

Long.

Parameters of eye Buckle hydraulic wire bending machine with pipe part assembly

The original wire diameter: 2.0-7.0 (mm)

Feeding length: 300 (mm)

Motor power: 5.5KW 1400rpm

Mechanical power: 1 set of hydraulic system

Mechanical size: 1580*1000*1580 (length × width × height)

Mechanical weight: 700-800KG