Description

APG series double crank high-speed stamping press machine

Features

· Widely used in stamping and forming of electronics, communication, computers, household appliances, furniture, performance tools (automobiles, motorcycles, bicycles), hardware parts, etc.

· Straight wall integrated frame for precision continuous die stamping.

·Without the opening throat disadvantage of C-type punching frame which can save mold maintenance costs.

· High-rigidity frame, the guide rail is on the center line of the punch and the support stroke is long, which ensures long-term dynamic stability and prolongs the life of the mold.

·The bottom area of the punch is 15~25% larger than the C-type punch, allowing the station numbers of mold projects to increase and the value added processing.

·High-torque wet brake clutch for long life and low maintenance cost; no pollution, low noise, and environmental protection. High security,

·High-affinity, versatile electronic electronic control system.

· Can be used with a variety of automation equipment, easy to operate.

·Electric punch adjustment device: This adjustment device uses a thin brake motor and operates with a button. Its advantages are accurate positioning, stable mechanism, and rapid adjustment.

·Easy punch adjustment device: Simple and reliable manual mold height adjustment equipment with 0.1mm indicator.

·Electric grease pump: automatic timing centralized lubrication pump and fault detection system to ensure smooth operation.

· Highly rigid body, small deformation of the fuselage, and greatly improved tool life.

·Low noise, low vibration, and low cutting noise.

·The number of strokes is adjustable.

·Hydraulic overload protection device, overload automatic emergency stop, protect punch and mold safety.

· Strong left and right eccentric load.

·The fixed-lock six-sided long guide has high precision.

·Human machine interface, easy to operate.

Specifications of APG series double crank high-speed stamping press machine

| Model | Unit | APG-60B | APG-80B | APG-125B | APG-200B | APG-300B |

|---|---|---|---|---|---|---|

| Capacity | Ton | 60 | 80 | 125 | 200 | 300 |

| Stroke | mm | 3.2 | 3.2 | 3.2 | 3.2 | 3.2 |

| Die Height | mm | 30 | 30 | 30 | 30 | 30 |

| Stroke per Minute | mm | 340 | 360 | 380 | 400 | 420 |

| Slide Adjustment | s.p.m | 200-550 | 200-550 | 200-500 | 150-350 | 100-300 |

| Slide Area | mm | 50 | 50 | 50 | 60 | 70 |

| Bolster Area | mm | 790 × 450 | 1000 × 550 | 1200 × 600 | 1700 × 700 | 2000 × 900 |

| Bed Opening ( LR×FB ) | mm | 850 × 600 | 1100 × 700 | 1300 × 800 | 1800 × 900 | 2000 × 1000 |

| Main Motor | kw.p | VS20 × 4 | VS22 × 4 | VS40 × 4 | VS50 × 4 | VS60 × 4 |

| Max.Weight of Upper Die | Kg/m² | 5 | 5 | 5 | 5 | 5 |

| Presses Dimension | mm | 2160×1250× 2995 | 3320 × 2565 × 2035 | 2750 × 1500 × 3742 | 3550 × 2000 × 4470 | 4050 × 2500 × 5700 |

| Presses Weight | Ton | 15 | 19 | 23 | 28.5 | 40 |

| Presses Precision | JB/T6580-93 | JB/T6580-93 | JB/T6580-93 | JB/T6580-93 | JB/T6580-93 |

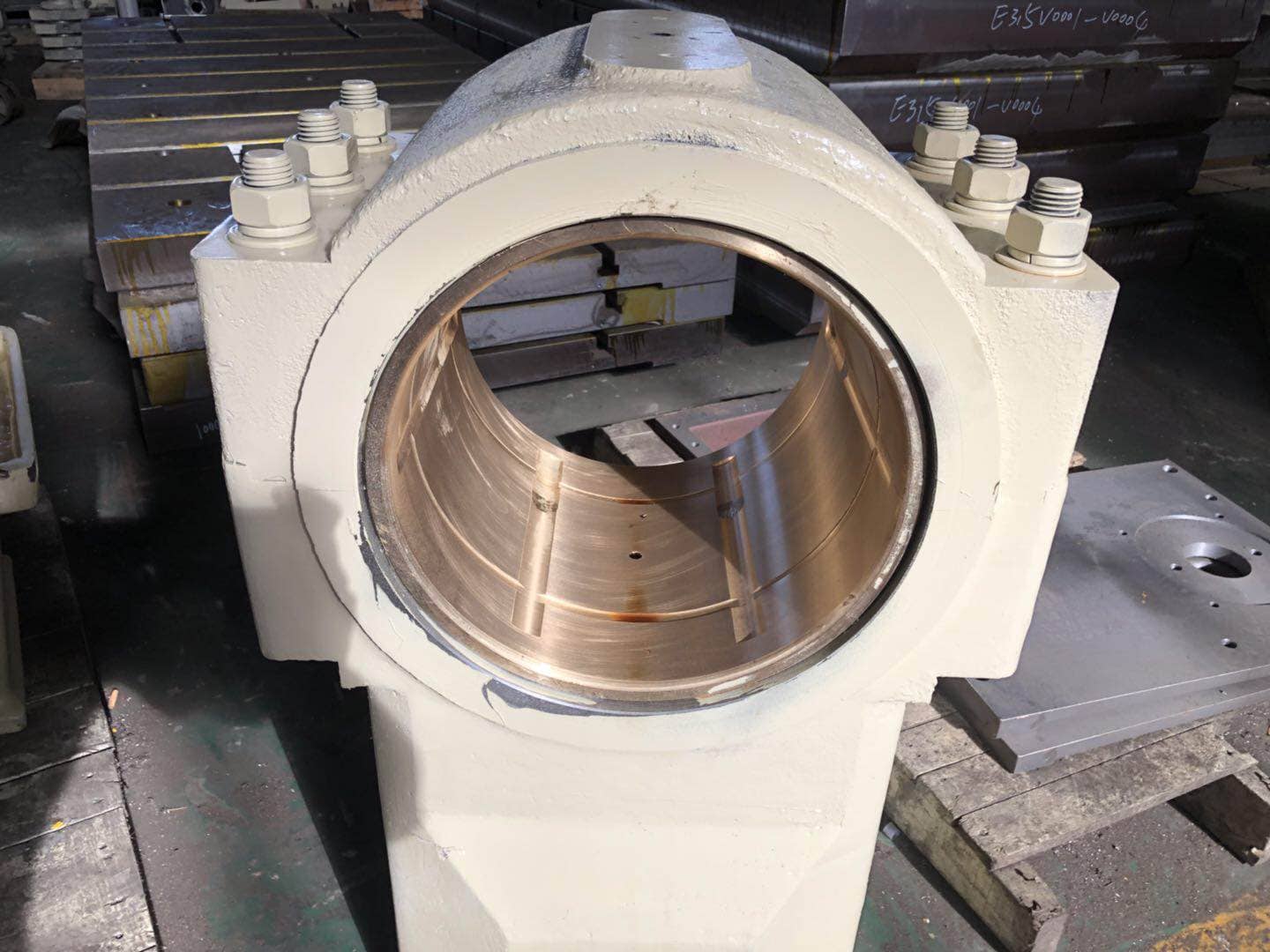

Copper anti wear slider of APG series double crank high-speed stamping press machine

Top quality copper anti wear sleeve of APG series double crank high-speed stamping press machine

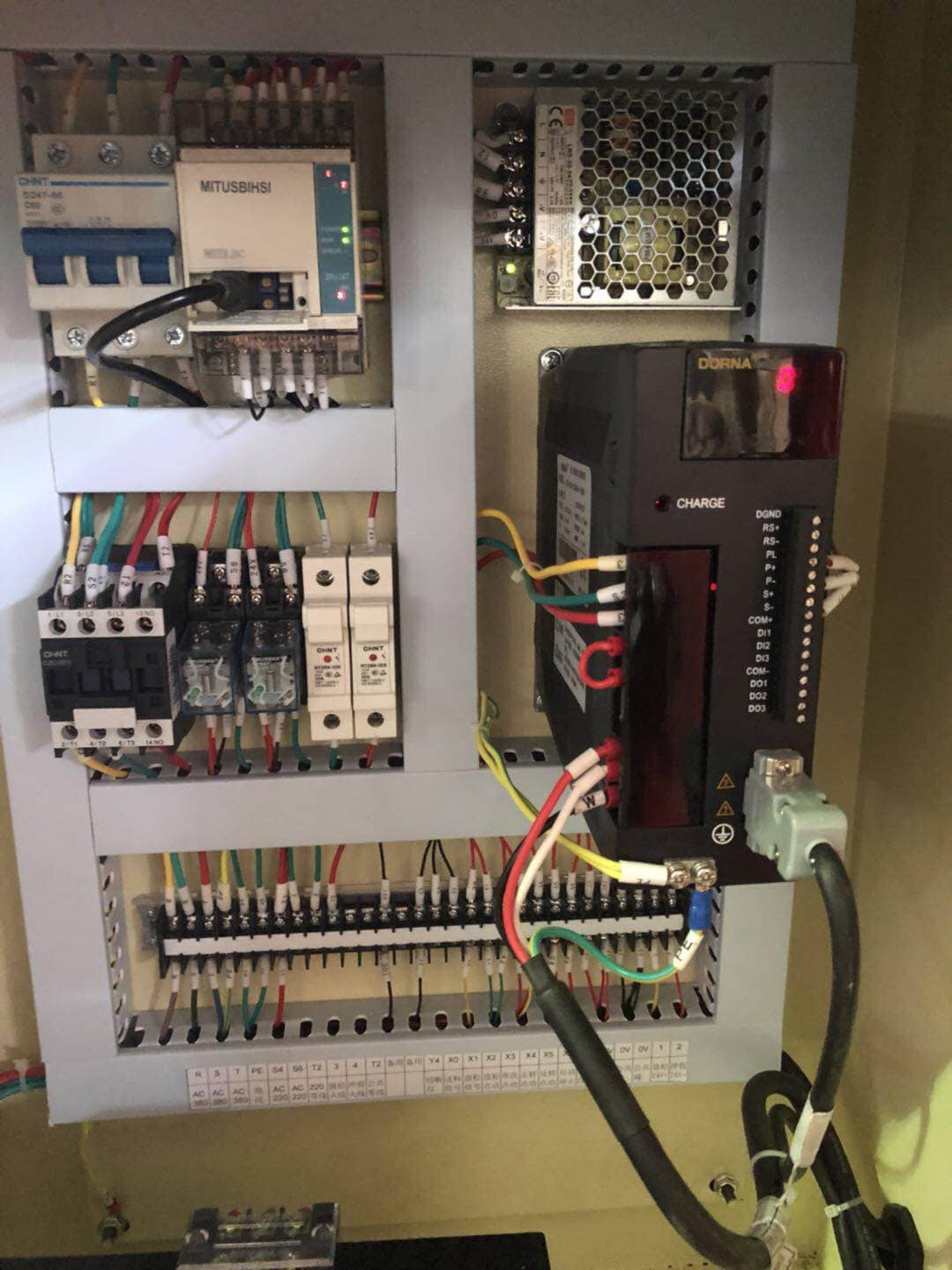

Delta inverter of APG series double crank high-speed stamping press machine

OMPI clutch used on APG series double crank high-speed stamping press machine

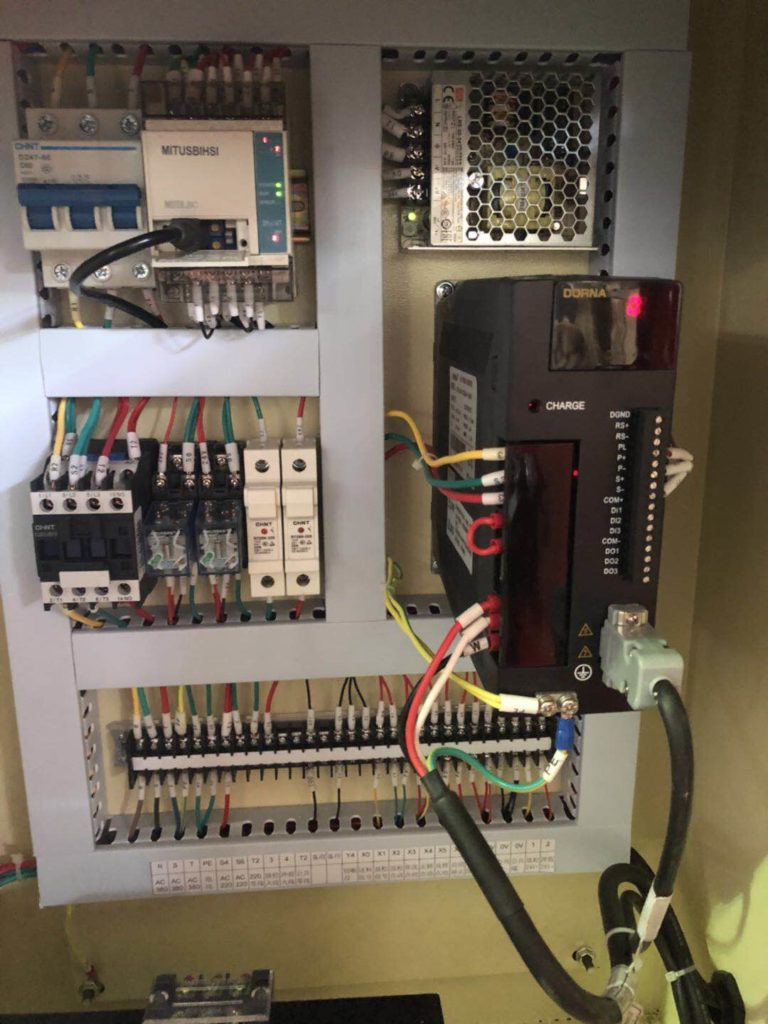

Dorna mitusbihsi chint famous brands electric components used one the stamping press

Cnc automatic strip feeder with touch screen of chinese and english language.